In modern industries such as aerospace, automotive, marine engineering, medical devices and high-performance sports equipment, the choice of fasteners plays a crucial role in safety and durability. Among the most common options are titanium bolts and steel bolts. Both have distinct advantages and limitations, and understanding the differences can help engineers, buyers, and manufacturers make the right decision.

Strength and Weight

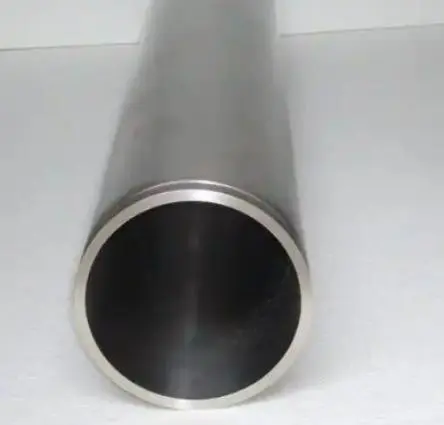

Steel bolts are traditionally known for their excellent tensile strength and cost-effectiveness. They perform well in structural applications where extreme load-bearing capacity is required. However, titanium bolts provide a unique advantage — offering comparable strength to high-grade steel bolts at nearly half the weight. For industries like aerospace and racing cars, where every gram matters, titanium fasteners are a game changer.

Corrosion Resistance

One of the most notable benefits of titanium bolts for sale is their outstanding corrosion resistance. Titanium forms a stable oxide layer that protects it from seawater, chemicals, and harsh environments. This makes titanium fasteners the preferred choice in marine, chemical, and medical applications. In contrast, steel bolts, even when stainless or coated, are more vulnerable to rust and long-term degradation.

Durability and Longevity

When it comes to fatigue strength and service life, titanium bolts outperform steel in many demanding applications. They maintain performance under cyclic loads and extreme conditions, ensuring reliability over time. While steel bolts may be more affordable initially, their shorter lifespan in corrosive environments can lead to higher long-term costs.

Machinability and Cost

Steel bolts are easier to machine, readily available, and more cost-efficient, making them the standard choice in general engineering and construction. On the other hand, titanium bolts require specialized machining and forging, which increases the production cost. However, in sectors where lightweight and corrosion resistance directly improve performance and safety, the investment in titanium fasteners is justified.

Application Comparison

Titanium Bolts: aerospace components, racing car fasteners, marine hardware, chemical equipment, medical implants, high-performance bicycles.

Steel Bolts: construction, machinery, automotive parts, heavy-duty equipment, general-purpose fastening.

Conclusion

When comparing Titanium Bolts vs Steel Bolts, the choice depends on the balance between cost, performance, and application environment. For industries requiring lightweight, high strength, and corrosion resistance, titanium bolts are the superior option. For general engineering and cost-sensitive projects, steel bolts remain the practical solution.

As industries continue to demand lightweight and durable fasteners, the trend shows an increasing shift towards titanium fasteners in critical applications.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية