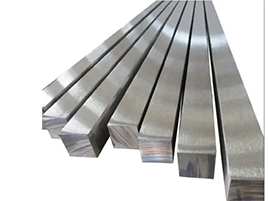

Why Choose BYC Ti Titanium Square Bars?

Uniform square cross-section for structural rigidity

Up to 45% lighter than stainless steel, with comparable strength

Excellent corrosion resistance in seawater, acids, and alkalis

Suitable for CNC machining and welding

Non-magnetic, biocompatible, and long service life

Titanium Square Bar Technical Specifications

Parameter | Specification | Notes |

Size Range | 6mm × 6mm – 100mm × 100mm | Custom sizes available |

Length Range | ≤6000mm | Cut-to-length available |

Grades Available | GR1, GR2, GR5, GR7, GR9 | ASTM B348 / AMS / ISO standards |

Surface Finish | Turned, Peeled, Polished | Mirror polish optional

|

Tolerance | ±0.1mm ----±0.5mm | Based on size & standard

|

Density | 4.51 g/cm³ | Lightweight, high strength |

Melting Point | ~1660°C | High-temp application ready

|

Titanium Square Bar Application Industries

Structural Engineering

Marine & Offshore

General Industry

Medical & Cleanroom

Titanium Square Bar Manufacturing Excellence

Precision forging from certified titanium billets

CNC machining for square cross-section uniformity

Ultrasonic, mechanical & chemical property testing

Full compliance with ASTM and customer specifications

EN10204-3.1 certificate available on request

Titanium Square Bar Packaging & Logistics

Moisture-proof plastic wrap + export-grade wooden crates

Suitable for sea, air, and land transportation

Custom labeling, palletizing & product traceability

Titanium Square Bar Customization Options

Non-standard square dimensions

Specialty titanium alloys available on request

Custom surface finishes & laser marking

OEM packaging & international shipping

Why Partner with BYC Ti Titanium Square Bar manufacturer?

Over 20 years of titanium manufacturing expertise

ISO 9001 / AS9100 certified production

Fast delivery, global logistics, and multilingual export support

One-stop service for titanium bar, plate, tube, and forgings

Titanium Square Bar Frequently Asked Questions

Q: Can square bars be used for load-bearing applications?

A: Yes, the uniform cross-section makes them ideal for structural components that require high strength and rigidity.

Q: Which grade is best for seawater environments?

A: Grade 2 and Grade 7 are highly recommended due to their superior corrosion resistance in chloride and saltwater exposure.

Q: Do you provide small-batch orders?

A: Yes, we support sample orders, trial production, and large-volume deliveries.

Q: What's your typical lead time?

A: Regular sizes ship in 5–7 business days. Custom dimensions take 2–3 weeks.

Contact Us Today

Looking for precision titanium square bar stock? Reach out to our technical team for a tailored quote and expert support.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية