Titanium Electrode Bars for Powder Production Features

Precision-Melted and Homogeneous

Using double vacuum arc remelting (VAR) or triple melt processes, each bar offers uniform composition throughout — reducing segregation, voids, and melt inconsistencies during atomization.

Chemically Clean

Low oxygen, nitrogen, and hydrogen levels help avoid powder contamination, especially critical when producing titanium powders for aerospace or biomedical applications.

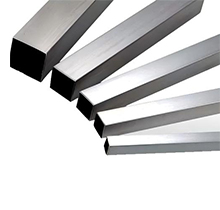

Tailored Dimensions for Smooth Feeding

Machined to tight tolerances, our bars fit directly into atomization furnaces without modification. We offer straightness control and surface finishes that improve feeding consistency and arc stability.

Proven in Industry

Our bars are in daily use at domestic and international powder production facilities. From large-scale commercial atomization to small-batch alloy development, we support it all.

Titanium Electrode Bars for Powder Production Specifications

Standard Grades:

Typical Diameters: 100 mm – 200 mm

Standard Lengths: 800 mm – 1500 mm (custom options available)

Surface Finish: Turned / Ground / Polished

Straightness: ≤ 1 mm/m

Density: ≥ 4.50 g/cm³

Certifications: ASTM B348, ISO 5832-2, AMS 4928 (as applicable)

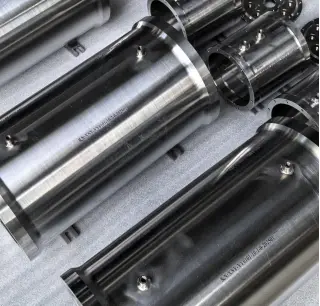

How Titanium Electrode Bars for Powder Production are Used

Our electrode bars are cut, clamped, and slowly melted in a controlled environment using either a plasma torch or induction furnace. As the molten tip drips or spins off, atomization occurs — creating fine, spherical titanium powder ready for use in:

Titanium 3D printing / Additive manufacturing

Coatings for turbines or biomedical devices

Metal injection molding (MIM)

Alloy R&D

Titanium Electrode Bars for Powder Production FAQs

How are the bars delivered?

Bars are cleaned, capped, and vacuum-packed with nitrogen protection where required. They're crated in heavy-duty wooden boxes with full handling instructions to prevent surface damage or moisture exposure.

Do you provide trial quantities for new atomizers?

Yes. We regularly supply 1–5 bar trial lots for new installations or custom alloy development.

What's the difference between Grade 5 and Grade 23 in electrode form?

Grade 5 offers slightly higher strength, suitable for general-purpose powder. Grade 23 has lower interstitials (especially oxygen), which makes it ideal for medical-grade powder production where ductility and biocompatibility are critical.

With over a decade of experience supplying titanium materials, we understand what powder producers need: consistency, traceability, and clean chemistry. Our dedicated production lines for electrode bars ensure fast turnaround, flexible sizing, and material customization.

We support both established powder producers and emerging AM powder startups with expert consultation, short lead times, and responsive service.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية