High Purity Titanium Powder Key Advantages

Exceptional Purity: Titanium ≥99.9%, ultra-low interstitials

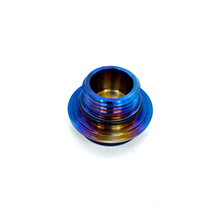

Optimized for Additive Manufacturing: Spherical morphology, tight PSD

Vacuum-Compatible: Free from halides, lubricants, or residual chlorides

Fully Traceable: Melt history, gas content, and PSD certified per batch

Flexible Production Routes: Gas or plasma atomized, HDH for angular forms

Medical & Aerospace Grade: Supports ASTM F1580, ISO 13485, AMS standards

High Purity Titanium Powder Applications

From titanium medical implants to laser-melted aerospace structures, this powder is engineered for:

Additive Manufacturing (SLM / EBM / DED)

High-performance medical implants and devices

Vacuum metallurgy and thin-film sputtering targets

Superconducting wire production (e.g., NbTi)

Titanium-based specialty ceramics and catalysts

Advanced energy systems (batteries, fuel cells)

High Purity Titanium Powder Specifications

Property | Value / Range |

Purity | ≥ 99.9% (3N to 4N grades available) |

Morphology | Spherical (atomized) or angular (HDH) |

Particle Size Distribution | 10–45 μm / 15–53 μm / custom ranges |

Oxygen Content | Typically < 500 ppm; down to 200 ppm |

Flowability (Hall / Carney) | < 25 s/50g (Hall); < 5 s (Carney) |

Tap Density | 2.5 – 3.8 g/cm³ |

Packaging | Argon-sealed bottles, drums, vacuum bags |

Why High Purity Titanium Powder Matters

The integrity of your end-use product depends on the powder it starts with. High-purity powder minimizes inclusions, improves fusion, and delivers superior mechanical and corrosion resistance. Whether you're melting layer-by-layer in an titanium 3D printing system or alloying in a high-vacuum furnace, BYC Ti's powder ensures your material starts clean and stays strong.

High Purity Titanium Powder Common Questions

How is this different from standard titanium powder?

Standard powders often contain higher levels of oxygen, nitrogen, and residual chlorides. High-purity powder is refined to prevent these, enabling use in critical environments like implants or vacuum processing.

Is this powder medical-grade certified?

Yes. When requested, we provide material compliant with ASTM F1580 and ISO 13485, suitable for biomedical production.

Can I request a custom particle size or chemistry?

Absolutely. Both are customizable during production or via post-processing (sieving, blending).

High Purity Titanium Powder Order & Delivery

MOQ: 1 kg for R&D samples; commercial scale up to 2,000 kg/month

Lead Time: 7–10 working days (stocked); 3–4 weeks for custom grades

Shipping: Air-safe packaging with argon seal; global delivery supported

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية