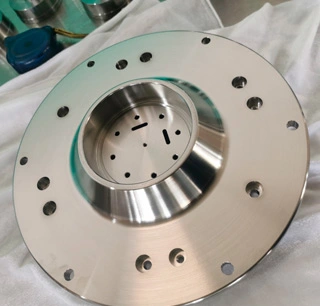

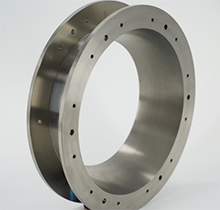

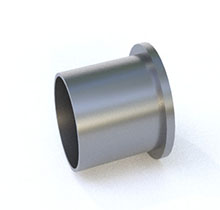

Titanium Forged Rings Main Features

· Material Grades: TA1, TA2, TA3, TA10, TC4 (Ti-6Al-4V), Ti-6Al-7Nb, Ti-6242

· Forging Type: Open die forging + ring rolling

· Outer Diameter Range: 100 mm – 2000 mm

· Wall Thickness: 10 mm – 150 mm

· Standards: ASTM B381, AMS4928, ISO 5832-2

· Surface Finish: Machined, rough turned, or customized

Titanium Forged Rings Applications

· Aerospace: Jet engine casings, structural rings

· Marine: Subsea flanges, pressure-resistant rings

· Chemical Processing: Heat exchanger supports, gasket rings

· Industrial Equipment: Bearing housings, rotating rings

· Medical: Large-diameter orthopedic devices

BYC Ti Titanium Forged Rings Advantages

· Excellent strength-to-weight ratio

· High corrosion resistance in aggressive environments

· Tight dimensional tolerances after ring rolling

· Support for custom machining and finishing

· All products tested for internal quality and compliance

Custom Titanium Forged Rings Service

We offer precision ring forging services tailored to your specific application needs. Whether you require a Ti-6Al-4V seamless ring or a large-diameter pure titanium ring, we can provide cost-effective, high-performance solutions with fast delivery and full documentation.

Titanium Forged Rings Quality Control & Certification

Each forged titanium ring undergoes:

- Ultrasonic Testing (UT)

- Dimensional Inspection

- Mechanical Testing (Tensile, Hardness)

- Third-party inspection available upon request

Certificates: EN 10204 3.1 / 3.2, ISO 9001, AS9100

Feel free to reach out with your specifications or drawings. We will provide a quote within 24 hours.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية