Tel: +86-17628187609

E-mail: fyy935627558@gmail.com

-

Titanium Products

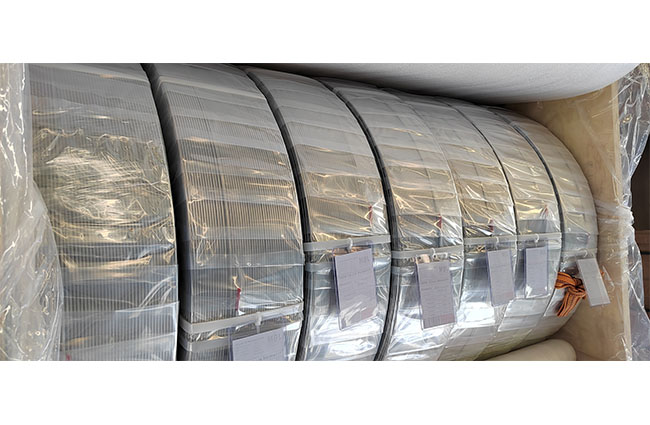

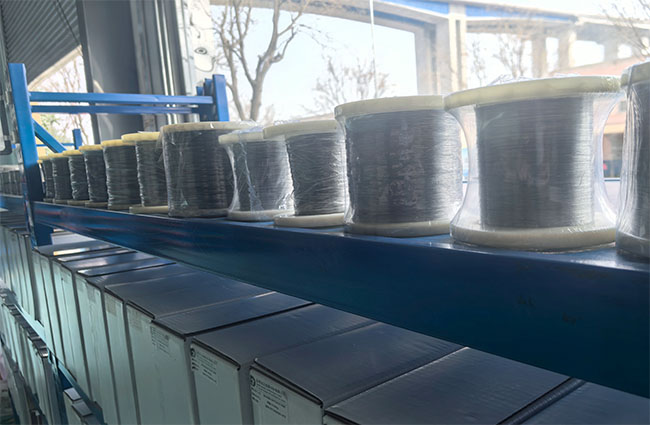

Titanium Rods & Bars Titanium Plates & Sheets Titanium Pipes & Tubes Titanium Wires Titanium Foils, Strips & Ribbons Titanium Standard Parts & Fittings Titanium Fasteners Titanium Forgings Titanium Castings Custom Titanium CNC Machining Parts Titanium 3D Printing Titanium Welding Materials Titanium Anodes Titanium Blocks Titanium Discs

-

Other Metals

- Company

- Capabilities

- News

- Contact Us

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية