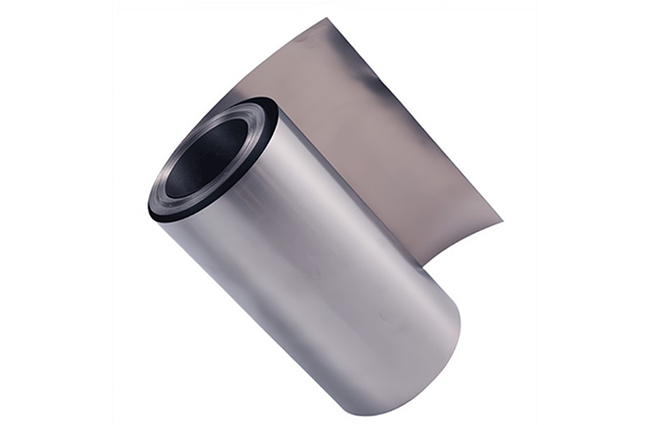

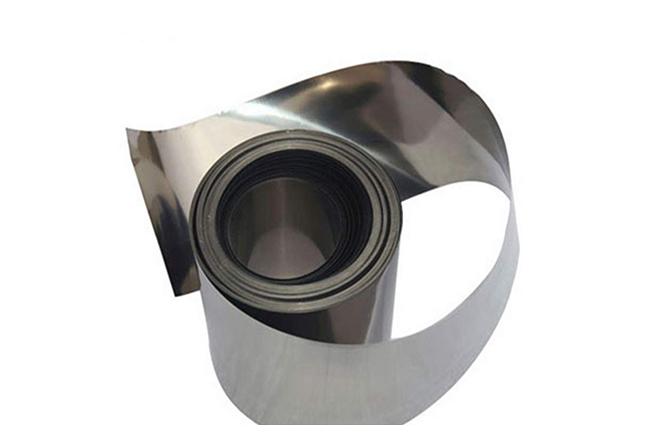

Thick Titanium Strip Key Features

Feature | Specification |

Thickness Range | 0.5 mm – 10 mm |

Width | 10 mm – 600 mm (customizable up to 1000 mm) |

Length/Form | Coil or straight strip (custom lengths available) |

Titanium Grades | ASTM Grade 1, 2, 3, 4, 5, 7, 9, 12 |

Tolerances | Tight tolerances per ASTM B265 or customer specifications |

Surface Finish | Pickled, bright, ground, or sandblasted |

Purity | ≥ 99.6% for commercially pure titanium grades |

Packaging | Wooden crate or steel-framed pallet with protective film wrapping |

Advantages of BYC Ti's Thick Titanium Strip

Structural Strength

High tensile strength and excellent fatigue resistance make it suitable for load-bearing and high-impact environments.

Extreme Corrosion Resistance

Inert in seawater, acids, alkalis, and chlorine-heavy environments — ideal for marine, chemical, and offshore equipment.

Thermal & Electrical Stability

Low thermal expansion and excellent resistance to thermal shock make it ideal for heat exchangers and reactor linings.

Fabrication Ready

Easily machined, welded, or stamped. Suitable for CNC cutting, waterjet processing, bending, and rolling.

Thick Titanium Strip Applications

Industry | Typical Uses |

Chemical Processing | Reactor linings, acid tanks, heat exchangers |

Aerospace & Defense | Airframe reinforcements, ballistic armor, fuel system components |

Automotive & EVs | Battery enclosures, structural supports, thermal protection panels |

Shipbuilding & Marine | Hull plating, anti-corrosion panels, propulsion systems |

Architecture & Art | Exterior panels, sculptures, structural accents |

Thick Titanium Strip Mechanical Properties (Example: Grade 5, 6.35 mm)

Property | Typical Value |

Yield Strength | ≥ 880 MPa |

Tensile Strength | ≥ 950 MPa |

Elongation | ≥ 10% |

Modulus of Elasticity | 114 GPa |

Density | 4.43 g/cm³ |

Hardness | HRC 30–36 |

Melting Point | 1660°C |

Thick Titanium Strip Customization & Services

Precision Slitting: Custom widths with laser or shear cutting

Edge Conditioning: Rounded, slit, deburred, or square edges available

Surface Treatments: Pickling, grinding, sandblasting, or customer-specified coatings

Material Certifications: Full mill test reports (MTC) and third-party inspection available

OEM Support: Small-batch prototyping or bulk manufacturing available for industrial customers

Thick Titanium Strip Quality & Compliance

BYC Ti thick strips are produced in accordance with:

ASTM B265, AMS 4911, AMS 4902, ISO 5832

ISO 9001:2015 certified manufacturing

Full traceability and lot-specific documentation

Thick Titanium Strip Ordering Information

Please provide the following when requesting a quote:

Desired grade (e.g., Grade 2, Grade 5)

Thickness, width, and length or coil form

Surface finish and edge treatment preferences

Quantity and delivery timeline

With a legacy of precision and innovation, BYC Ti is a leading titanium solutions provider. Our thick titanium strip and titanium foils are designed for industrial performance and engineered with integrity. Whether you need strength under pressure or resistance against corrosion, our titanium delivers.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية