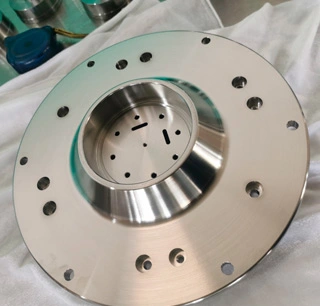

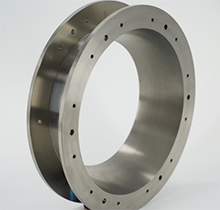

Titanium Forged Discs Main Features

· Material Grades: TA1, TA2, TA3, TA10, TC4 (Ti-6Al-4V), Ti-6Al-7Nb, Ti-6246

· Forging Type: Open die forging / Closed die forging

· Diameter Range: 50 mm – 1000 mm

· Thickness Range: 10 mm – 200 mm

· Standards: ASTM B381, AMS4928, ISO 5832-3 (Medical), etc.

· Surface Finish: Machined, rough turned, or customized

Titanium Forged Discs Applications

· Aerospace: Engine components, turbine parts

· Marine: Propulsion systems, subsea equipment

· Chemical Processing: Corrosion-resistant equipment

· Medical: Orthopedic base discs, surgical platforms

· Industrial: High-performance mechanical systems

Advantages of Our Titanium Disc Forging

· Superior strength-to-weight ratio

· Excellent corrosion resistance in seawater and chemical environments

· Outstanding fatigue and fracture toughness

· Custom sizes and machining available

· 100% ultrasonic and mechanical testing provided

Custom Titanium Forging Service

We provide custom titanium forging solutions based on your technical drawings and performance requirements. Whether you need a standard Ti-6Al-4V forged disc or a complex near-net shape titanium part, our forging expertise ensures high precision and fast lead time.

Titanium Forged Discs Quality Control & Certification

Each forged titanium disc undergoes:

- Ultrasonic Testing (UT)

- Chemical Composition Analysis

- Mechanical Property Test (Tensile, Elongation, Yield)

- Third-party inspection available upon request

Certificates: EN 10204 3.1 / 3.2, ISO 9001, AS9100 (upon requirement)

Please contact us for a quote or technical consultation. We respond within 24 hours.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية