Medium Titanium Powder Features

Balanced Particle Size Distribution

Typical range: 45–105 μm (customizable).

Offers excellent compromise between powder flow (ideal for DED & cold spray) and surface resolution (suitable for coarse L-PBF or binder jetting systems).

Economical and Versatile

Lower production cost compared to ultra-fine powder, with less strict handling requirements — making it ideal for production-scale additive and spray systems.

Compatible Across Industries

Used in automotive, energy, tooling, and aerospace for parts that don’t require medical-grade refinement but still demand structural integrity.

Medium Titanium Powder Key Technical Details

Attribute | Value / Range |

Particle Size | 45–105 μm (typical) |

Morphology | >95% spherical |

Production Method | Gas Atomization / Plasma Atomization |

Purity (Ti content) | ≥ 99.5% |

Oxygen Content | ≤ 0.20% (Grade 5) / ≤ 0.13% (Grade 23) |

Tap Density | ~2.6 g/cm³ |

Flowability (Hall) | 20–26 sec / 50g |

Sinterability | Good (binder jetting, MIM) |

Medium Titanium Powder Available Grades

Ti-6Al-4V (Grade 5): High strength, widely used in AM and coatings

Ti-6Al-4V ELI (Grade 23): Lower oxygen, improved ductility (optional)

CP Titanium (Grades 2 & 4): For corrosion-resistant and lightweight applications

Custom Alloys: Available for R&D and specialty applications

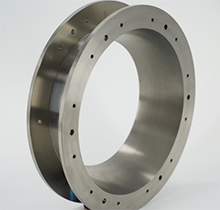

Medium Titanium Powder Applications

Directed Energy Deposition (DED): Structural repair and large-format AM

Cold Spray: Protective coatings for corrosion or wear

Binder Jetting: Lightweight lattice parts, optimized sintering

Metal Injection Molding (MIM): Mass-produced titanium components

Sintered filters & porous structures: For heat exchangers, fuel cells, etc.

Medium Titanium Powder Packaging & Handling

Standard Pack Sizes: 10 kg / 25 kg / 50 kg

Packaging: Double-sealed foil bags, nitrogen-purged, in metal drums

Shelf Life: 12 months under dry, sealed storage

Medium Titanium Powder FAQs

Q: What's the minimum order quantity (MOQ)?

A: Our MOQ for standard grades is 10 kg. We also support small-quantity orders for R&D use.

Q: Is this powder reusable?

A: Yes, when properly sieved and handled. We can provide reuse protocols upon request, tailored to your AM process.

Q: Can I request a custom particle size range?

A: Absolutely. We can adjust PSD to match your process — just share your equipment and application.

With rich experience in titanium metallurgy, BYC Ti is a recognized supplier of high-performance titanium materials for the titanium 3D printing, medical, and aerospace sectors. We offer a full powder portfolio — from ultra-fine to coarse — and support customers with responsive service, global logistics, and technical guidance from atomization to application.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية