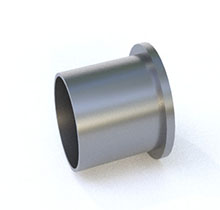

Titanium Blind Flange Key Features

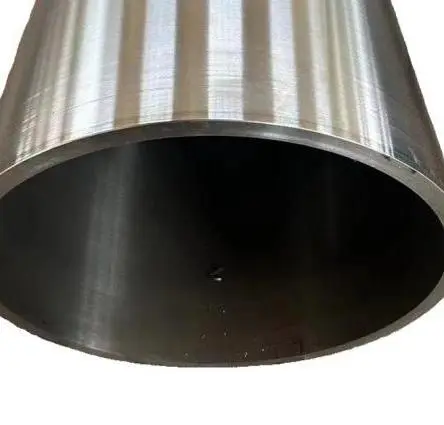

· Made of pure titanium or titanium alloy for maximum corrosion resistance

· Durable and lightweight

· Excellent sealing performance for pipe ends

· Available in a variety of pressure ratings and sizes

· Easy to install and remove for inspection and maintenance

Titanium Blind Flange Applications

· Chemical and petrochemical industries

· Oil and gas pipelines

· Desalination and marine applications

· Aerospace and defense systems

· Medical devices and process equipment

· Power plants and industrial fluid control systems

Titanium Blind Flange Available Sizes & Standards

Size (NPS) | Outside Diameter (OD) | Thickness | Bolt Circle Diameter | Number of Bolt Holes | Flange Standards |

1/2" (DN15) | 89 mm | 11 mm | 60.3 mm | 4 | ASME B16.5, EN1092 |

1" (DN25) | 108 mm | 13 mm | 79.4 mm | 4 | ASME B16.5, JIS |

2" (DN50) | 150 mm | 16 mm | 120.7 mm | 4 or 8 | ASME B16.5 |

4" (DN100) | 229 mm | 19 mm | 190.5 mm | 8 | ASME B16.5 |

6" (DN150) | 279 mm | 21 mm | 241.3 mm | 8 | ASME B16.5 |

Custom | On request | On request | On request | On request | Drawings accepted |

Titanium Blind FlangeMaterial Grades

Grade | Standard | Description |

Gr1 | ASTM B381 / B363 | Commercially pure titanium, excellent corrosion resistance |

Gr2 | ASTM B381 / B363 | Most widely used titanium grade with good strength and corrosion resistance |

Gr5 | Ti-6Al-4V | High strength alloy, ideal for aerospace and industrial parts |

Gr7 | Ti + Pd | Outstanding resistance to reducing acids |

Gr12 | Ti + Mo + Ni | High performance in chloride-containing environments |

Titanium Blind Flange Packaging & Delivery

• Lead Time: 7–25 days depending on quantity

• Packing: Export-grade plywood cases or as required

• Delivery Terms: EXW, FOB, CIF, DAP

• Transport Methods: Air, Sea, Express (DHL/FedEx/UPS)

Why Choose Us for Titanium Blind Flange?

· Located in China Titanium Valley – Baoji

· Over 10 years of manufacturing experience

· Strict quality control and inspection

· Fast response, technical support, and customized production

· Global exports with stable customer base

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية