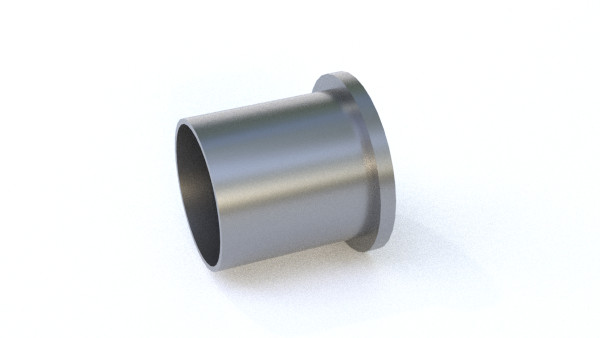

Titanium Stub End Key Features

· Corrosion-resistant in seawater, acidic, and chlorinated environments

· Excellent weldability and mechanical strength

· Lightweight — up to 45% lighter than stainless steel

· Compatible with lap joint flanges

· Precision machined to ensure secure fit and seal

Titanium Stub End Specifications

Parameter | Specification | Notes |

Size Range | 1/2" – 12" | Custom sizes available |

Wall Thickness | SCH10 – SCH80 | Per customer requirement |

Grades Available | GR2, GR5, GR7, GR9 | ASTM B363 / ASME SB363 |

Standards | ANSI, DIN, JIS, ASTM | International compatibility |

Surface Finish | Pickled, Sand-blasted, Polished | Smooth internal/external finish |

Connection Type | Butt-weld | For high-performance systems |

Titanium Stub End Applications

· Aerospace: Lightweight pipeline fittings

· Chemical Processing: Corrosive pipeline systems

· Marine Engineering: Saltwater systems and junctions

· Industrial Equipment: High-purity process lines

· Medical & Cleanroom: Biocompatible, non-toxic installations

Titanium Stub End Packaging & Delivery

· Individually packed in plastic bags and wooden crates

· Laser marking, labeling, and full traceability available

· Global shipping by air, sea, or land freight

Why Choose BYC Ti for Titanium Stub End?

· 20+ years of experience in titanium processing

· ISO 9001 & AS9100 certified manufacturing

· Fast lead times and OEM customization

· Strict quality control for every batch

Request a Quote Today. Send us your required dimensions, material grade, and quantity. We will reply within 24 hours with a competitive quote and lead time.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية