Titanium Wire for 3D Printing Key Specifications

CP Titanium (Grade 1–4) – for high corrosion resistance

Ti-6Al-4V (Grade 5, Grade 23) – for strength-critical applications

Other Alloys: Ti-6Al-7Nb, Ti-3Al-2.5V, or custom on request

Titanium Wire for 3D Printing Product Features

Engineered for Additive Manufacturing

Precision-drawn for smooth, uninterrupted wire feeding — no snags, no fluctuations. Compatible with DED, WAAM, and robotic welding systems.

High Strength & Corrosion Resistance

Produced from aerospace-grade feedstock to ensure excellent mechanical properties and resistance to oxidation or saltwater exposure.

Clean Surface, Low Oxygen Content

Vacuum annealed and surface cleaned to minimize inclusions, outgassing, and contamination — ensuring strong layer adhesion and repeatable builds.

Easy to Weld & Machine

Offers stable arc characteristics and clean deposition paths. Post-build machining is straightforward thanks to controlled microstructure.

Titanium Wire for 3D Printing Application Fields

Titanium Wire for 3D Printing Properties (Ti-6Al-4V, Grade 5)

Property | Typical Value |

Purity | ≥ 99.5% |

Tensile Strength | 900–1050 MPa |

Yield Strength | ≥ 830 MPa |

Elongation | ≥ 14% |

Oxygen Content | ≤ 0.20% |

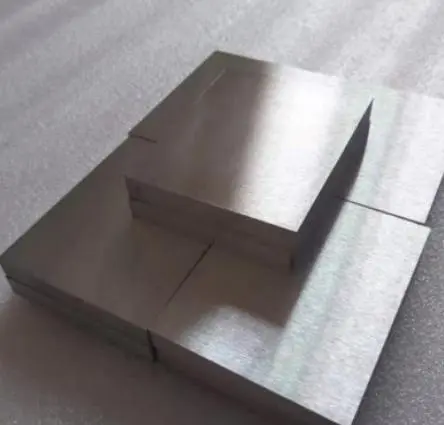

Wire Surface | Bright, free of oil or oxide |

Titanium Wire for 3D Printing FAQs

Q: What wire sizes do you support for DED and WAAM?

A: Our standard diameters range from 1.0 mm to 3.2 mm. Custom sizes outside this range can be produced based on order volume.

Q: How does your titanium wire perform in WAAM systems?

A: Customers report excellent feed consistency, low porosity in printed layers, and strong metallurgical bonding — particularly with Ti-6Al-4V.

Q: Can I order small batches for testing?

A: Absolutely. We offer pilot quantities for R&D and can scale up quickly for production needs.

About BYC Ti 3D Printing Titanium Wire Manufacturer

BYC Ti is a trusted supplier of high-performance titanium materials, serving additive manufacturing leaders in aerospace, medical, energy, and research. With rigorous quality control, and global export support, we help customers build smarter with titanium 3D printing — layer by layer.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية