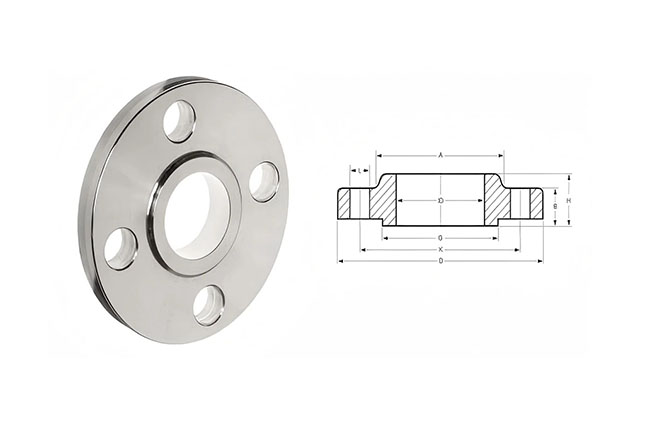

Titanium Slip-on Flange Key Features

· Excellent corrosion resistance to acids, chlorides, and seawater

· High strength-to-weight ratio

· Superior welding and fabrication properties

· Lightweight and durable

· Long service life in harsh environments

Titanium Slip-on Flange Applications

· Chemical and petrochemical industries

· Desalination and marine engineering

· Aerospace and defense systems

· Medical equipment and implants

· Power generation and energy sectors

· 3D printing & additive manufacturing systems (fluid/gas pipelines)

Titanium Slip-on Flange Available Sizes & Standards

Size (NPS) | Outside Diameter (OD) | Thickness | Bolt Circle Diameter | Number of Bolt Holes | Flange Standards |

1/2" (DN15) | 89 mm | 11 mm | 60.3 mm | 4 | ASME B16.5, EN1092 |

1" (DN25) | 108 mm | 13 mm | 79.4 mm | 4 | ASME B16.5, JIS |

2" (DN50) | 150 mm | 16 mm | 120.7 mm | 4 or 8 | ASME B16.5 |

4" (DN100) | 229 mm | 19 mm | 190.5 mm | 8 | ASME B16.5 |

6" (DN150) | 279 mm | 21 mm | 241.3 mm | 8 | ASME B16.5 |

Custom | On request | On request | On request | On request | Drawings accepted |

Titanium Slip-on Flange Material Grades

Grade | Standard | Description |

Gr1 | ASTM B381 / B363 | Commercially pure titanium, excellent corrosion resistance, good ductility |

Gr2 | ASTM B381 / B363 | Most commonly used, balanced strength and formability |

Gr5 | Ti-6Al-4V | High strength, commonly used in aerospace & high-performance parts |

Gr7 | Ti + Pd | Exceptional resistance to reducing acids like hydrochloric acid |

Gr12 | Ti + Mo + Ni | Excellent corrosion resistance in acidic and chloride environments |

Titanium Slip-on Flange Packaging & Delivery

• Lead Time: 7–25 days depending on quantity

• Packing: Plywood case or custom packing upon request

• Delivery Terms: EXW, FOB, CIF, DAP available

• Shipping: DHL / FedEx / UPS / Air / Sea

Why Choose Us for Titanium Slip-on Flange?

· Over 10 years of experience in titanium flange production

· In-house CNC machining and non-destructive testing

· Exported to over 30 countries

· Fast response and engineering support

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية