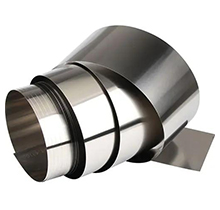

Titanium Ribbon Key Specifications

Parameter | Specification |

Thickness Range | 0.02 mm – 0.5 mm |

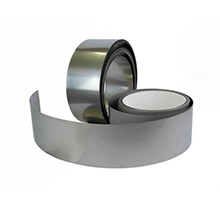

Width Range | 2 mm – 100 mm |

Form Factor | Continuous coil or custom-cut strips |

Alloy Grades | Ti-6Al-4V (Grade 5), Ti-6Al-7Nb, Ti-3Al-2.5V, Beta C, Grade 9, others |

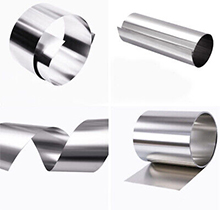

Surface Finish | Bright rolled, matte, etched, oxide-free |

Hardness Options | Annealed, cold-worked, or aged |

Packaging | Vacuum-sealed on antistatic spools or reels; cleanroom packaging optional |

Titanium Ribbon Advantages

High Strength with Lightweight Performance. Our titanium mesh ribbon delivers elevated tensile strength at minimal weight, making them ideal for compact components exposed to high mechanical stress.

Electrochemical Stability. Titanium wire mesh ribbons are ideal for battery and energy systems due to their excellent conductivity, heat resistance, and corrosion immunity in harsh environments.

Biocompatibility for Medical Innovation. Medical-grade alloys such as Ti-6Al-7Nb and Ti-3Al-2.5V are safe for internal human contact, offering superior fatigue resistance and MRI compatibility.

Ultra-Precise Fabrication. Easily adaptable to precision machining, laser welding, etching, and microforming processes — the titanium mesh ribbon is highly versatile for high-tech integration.

Titanium Ribbon Applications

Aerospace and aviation engineers use titanium alloy ribbon in signal cable shielding, lightweight connector strips, and thermal sensors that must withstand vibration and extreme temperature changes.

In medical device manufacturing, titanium ribbon materials are selected for implantable leads, neurostimulation wires, and sensor components requiring full biocompatibility and micro-scale durability.

Battery and energy system developers rely on titanium alloy ribbons for flexible current collectors, anode tabs, and heat-resistant battery enclosures in electric vehicles and portable electronics.

Advanced electronics and MEMS manufacturers incorporate titanium ribbon in flexible printed circuits, micro-heaters, and high-frequency shielding, where minimal weight and robust electrical stability are essential.

In scientific and cleanroom environments, titanium ribbon serves in high-vacuum assemblies, sputtering targets, and as substrates for experimental thin film deposition.

Why Choose BYC-TI Titanium Ribbon

BYCTI Titanium Ribbon with customization, precision, and quality is a good choice for industries requiring high-performance titanium solutions. Our advanced manufacturing capabilities and rigorous quality standards ensure that our titanium mesh ribbons meet the most demanding specifications for mechanical, electrical, and biomedical applications.

Titanium Ribbon Customization & Services

Custom Alloys & Tempers: Alloys engineered to meet specific mechanical, electrical, or biomedical needs

Micro-Tolerance Control: Thickness precision to ±0.002 mm

Edge Finishing: Rounded or square edges for safety and performance

Surface Treatments: Oxide-free, chemically cleaned, or textured

Rapid Prototyping: Small batch options for development and testing

Titanium Ribbon Certifications & Quality Assurance

Our titanium wire mesh ribbons are manufactured under ISO 9001:2015-certified systems. We provide full traceability and mill test certificates (MTCs) for every order, with materials conforming to industry-leading standards, including:

ASTM B265

AMS 4911 / AMS 4930

ASTM F136 / F1295 (for medical-grade applications)

With BYCTI Titanium Ribbon, you gain a partner dedicated to delivering customized, high-precision solutions backed by rigorous quality assurance, empowering your projects with reliability and performance.

Titanium Ribbon FAQs

Q: What's the minimum order quantity (MOQ) for titanium alloy ribbon?

A: MOQ depends on the alloy and ribbon dimensions, but small prototype quantities are available starting from 5 meters.

Q: Can I request a specific alloy not listed on your site?

A: Yes. We can produce custom titanium alloys or match your proprietary material specs upon request.

Q: Is the ribbon suitable for cleanroom or medical-grade environments?

A: Absolutely. We offer cleanroom packaging and bio-compatible grades with full traceability and documentation.

Q: How to Bulk Order Titanium Ribbon

A: To get started, send us the following: Desired alloy and grade; Thickness and width; Surface finish and quantity; Application details (optional, for tailored solutions)

With a legacy of precision and innovation, BYC Ti is a leading titanium solutions provider. Our titanium ribbon and titanium foils are designed for industrial performance and engineered with integrity. Whether you need strength under pressure or resistance against corrosion, our titanium delivers.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية