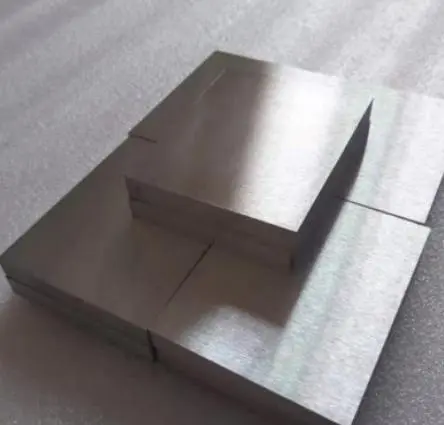

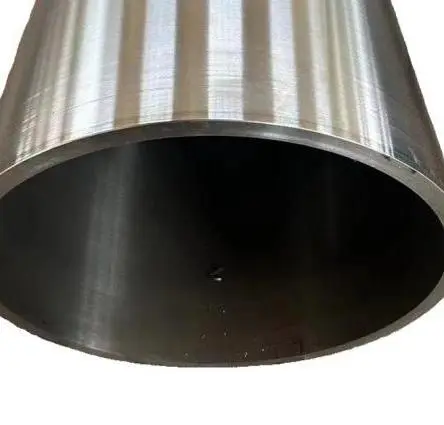

Titanium Square Tube Technical Specifications

Parameter | Specification |

Standards | ASTM B338, ASME SB338, DIN, JIS |

Size Range | 5–60mm sidewalls (custom lengths up to 6m) |

Wall Thickness | 0.2–8.0mm (thin-walled options available) |

Tolerances | ±0.1mm (precision cold-drawn) |

Surface Finish | Polished, bead-blasted, anodized |

Titanium Square Tubing Material Options & Properties

Grade | Key Features | Best For |

Grade 1 (CP Titanium) | Maximum ductility, cost-effective | Chemical processing, marine |

Grade 2 | Balanced strength & corrosion resistance | Architectural, general industrial |

Grade 5 (Ti-6Al-4V) | Aerospace-grade strength | Aircraft frames, racing components |

Grade 7 (Ti-0.15Pd) | Superior acid resistance | Chemical plants, offshore rigs |

Grade 23 (Ti-6Al-4V ELI) | Medical-grade, low interstitial | Implants, prosthetics |

Titanium Square Tubing Applications

Titanium Square Tubing in Aerospace & Defense

Titanium square tubes are essential in aerospace for their superior strength-to-weight ratio and durability. Grade 5 titanium square tube supports airframe structures like fuselage frames and wing spars, minimizing weight while ensuring strength. Landing gear utilizes lightweight, stress-resistant titanium rectangular tubing for reliable performance. Spacecraft frameworks, including satellites, depend on titanium's thermal stability in harsh space conditions. Drones benefit from corrosion resistance and vibration damping, enhancing airframe efficiency. Helicopter rotors leverage titanium square tube's fatigue resistance for safe, dynamic load handling.

Titanium Square Tubing in Marine & Offshore

Titanium square tubes excel in marine environments due to their corrosion resistance and lightweight design. Grade 7 titanium rectangular tubing forms durable subsea pipelines, resisting deepwater corrosion. Ship superstructures use titanium square tube for decking and railings, withstanding saltwater and reducing maintenance. Desalination plants employ titanium rectangular tubing in heat exchangers, enduring harsh chemicals. Offshore walkways feature non-slip titanium surfaces, while sailboat masts leverage titanium's strength for enhanced performance and longevity.

Titanium Square Tubing in Medical & Healthcare

Titanium square tubes are vital in medical applications for biocompatibility. Grade 23 titanium rectangular tubing crafts surgical implants, integrating seamlessly with the body. MRI machines use non-magnetic titanium square tube components. Dental chairs and mobility aids like wheelchairs benefit from lightweight, hygienic titanium. Sterilization racks rely on titanium rectangular tubing's corrosion resistance for autoclave durability.

Titanium Square Tubing in Chemical Processing

Titanium square tubes withstand aggressive chemical environments. Grade 7 titanium rectangular tubing supports reactor vessels, offering acid resistance. Heat exchangers and piping systems use corrosion-resistant titanium square tube for reliability. Electroplating tanks and pharmaceutical cleanrooms employ titanium rectangular tubing for durability and hygiene compliance.

Titanium Square Tubing in Architecture & Construction

Titanium square tubes enhance architecture with durability and aesthetics. They support weather-resistant building façades and seismic bracing using titanium rectangular tubing for earthquake resilience. Museum displays use non-corrosive titanium square tube framing. Pool components resist chlorine, and high-end interiors feature elegant, functional titanium elements.

Titanium Square Tubing FAQs

Q: Can you supply thin-walled tubes (≤1mm)?

A: Yes, we specialize in 0.2–1.0mm wall thicknesses for medical/industrial use. If you are interested in our thin - walled titanium tubing for sale, please feel free to contact us for more details

Q: Does Grade 7 titanium resist sulfuric acid?

A: Yes, Grade 7 (Ti-0.15Pd) is ideal for acidic environments.

Q: What's the MOQ for custom sizes?

A: 100kg for standard alloys; contact us for small-batch medical-grade orders.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية