Platinized Titanium Anode Key Features

1. Exceptional Corrosion Resistance: Titanium, as the substrate material, already has remarkable corrosion resistance. The additional platinum coating further enhances this property, allowing the anode to withstand harsh electrolyte environments for an extended period. This makes it suitable for use in industries where corrosion is a major concern, such as electroplating, water treatment, and chemical processing.

2. High Electro - Catalytic Activity: Platinum is known for its outstanding electro - catalytic properties. The platinized titanium anode can effectively catalyze electrochemical reactions, promoting higher reaction rates and current efficiencies. In applications like electrolysis, it enables more efficient conversion of electrical energy into chemical energy.

3. Long - Lasting Durability: Thanks to the combination of the corrosion - resistant titanium substrate and the wear - resistant platinum coating, our platinized titanium anode has an extended service life. It can maintain stable performance over a long time, reducing the frequency of replacement and thus lowering overall operating costs.

4. Dimensional Stability: The anode maintains its shape and size during operation, ensuring consistent performance. This is crucial for applications where precise control of the anode's geometry is required, such as in electroplating processes to achieve uniform plating thickness.

5. Lightweight Design: Compared to some traditional anode materials, titanium is lightweight. The platinized titanium anode inherits this advantage, making it easier to handle and install, especially in large - scale systems where weight can be a limiting factor.

Platinized Titanium Anode Specifications

1. Substrate Material: High - purity titanium (Grade 1 or Grade 2, depending on customer requirements). Titanium provides a stable and corrosion - resistant base for the platinum coating.

2. Coating Material: Pure platinum with a purity of 99.95% or higher. The high - purity platinum coating ensures excellent electro - catalytic performance.

3. Coating Thickness: The coating thickness can be customized in the range of 0.76 - 15 microns. Different applications may require different coating thicknesses to optimize performance. For example, in applications with high - current density and strong corrosive environments, a thicker coating may be preferred.

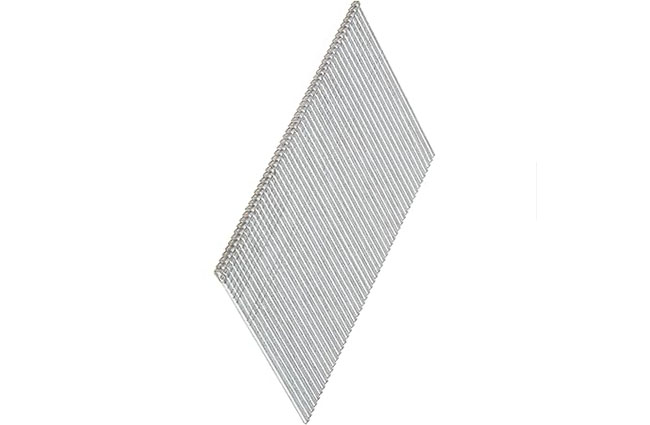

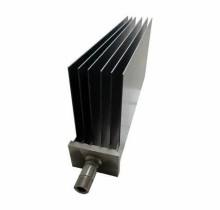

4. Anode Shape: Available in various shapes including plate, tube, mesh, rod, etc. We can also provide custom - shaped anodes according to specific customer needs. The shape of the anode is designed to maximize the surface area in contact with the electrolyte, improving the efficiency of electrochemical reactions.

5. Working Current: Can withstand a working current density of less than 5000 A/sq m, ensuring reliable operation under high - current conditions.

6. Noble Metal Content: The noble metal (platinum) content is greater than 15 g/sq m, guaranteeing high - quality electro - catalytic performance.

7. Operating Temperature: Suitable for use at temperatures below 80 degrees Celsius. This temperature range covers most common industrial applications.

Platinized Titanium Anode Applications

1. Electroplating: Ideal for hard chrome electroplating, precious metal electroplating (such as rhodium, platinum, and gold baths). In hard chrome plating, the platinized titanium anode can provide a stable current source, resulting in a uniform and high - quality chrome coating. In precious metal electroplating, it helps to achieve accurate control of the plating process, ensuring the deposition of a smooth and adherent precious metal layer.

2. Cathodic Protection: Used for the internal protection of condensers, process equipment, water tanks, pipelines, and reinforced concrete structures. By acting as an anode, it sacrifices itself (in a controlled way) to protect the metal structures from corrosion. The long - lasting durability of the platinized titanium anode makes it a reliable choice for long - term cathodic protection applications.

3. Water Treatment: In water treatment applications, such as in the production of ionized water by tap - water electrolysis. The anode can effectively participate in the electrolysis process, helping to adjust the chemical composition of water, for example, by generating reactive oxygen species or changing the pH value. It can also be used in wastewater treatment to facilitate electrochemical oxidation reactions for the degradation of pollutants.

4. Chemical Sensors: The high electro - catalytic activity and stability of the platinized titanium anode make it suitable for use in chemical sensors. It can detect and respond to changes in the electrochemical environment of the analyte, enabling the accurate detection of various chemical substances.

Platinized Titanium Anode Manufacturing Process

Our platinized titanium anodes are manufactured using advanced techniques. First, the titanium substrate undergoes a series of surface treatments to ensure a clean and smooth surface, which is essential for the subsequent platinum coating. Then, the platinum coating is applied through a precise plating process, such as electroplating or chemical vapor deposition. During the coating process, strict quality control is implemented to ensure a uniform coating thickness and strong adhesion between the platinum layer and the titanium substrate. After coating, the anodes are carefully inspected to meet our high - quality standards.

Platinized Titanium Anode Quality Assurance

BYC Ti is committed to providing high - quality products. All our platinized titanium anodes are manufactured in accordance with international quality standards, such as ISO standards. We have a comprehensive quality control system in place, starting from the selection of raw materials to the final inspection of the finished products. Each anode is thoroughly tested for its electrochemical performance, corrosion resistance, and dimensional accuracy before leaving the factory. In addition, we offer a 2 - year warranty for our products, ensuring customer satisfaction.

Customization Platinized Titanium Anode Services

We understand that different customers may have specific requirements for their anodes. Therefore, BYC Ti offers customization services. We can customize the anode's size, shape, coating thickness, and even the combination of substrate and coating materials according to your needs. Our experienced engineering team is ready to work with you to develop the most suitable anode solution for your application.

Why Choose BYC Ti's Platinized Titanium Anode?

1. Technical Expertise: With years of experience in the field of electrode materials, our R & D and production teams have in - depth knowledge and expertise. We are constantly exploring and innovating to improve the performance of our products.

2. Quality Products: Our strict quality control system ensures that every platinized titanium anode leaving our factory meets the highest quality standards. You can trust our products

for their reliability and long - term performance.

3. Customization Options: The ability to provide customized solutions allows us to meet the diverse needs of our customers. Whether you need a standard - sized anode or a highly customized one, we can fulfill your requirements.

4. Competitive Pricing: We offer our high - quality platinized titanium anodes at competitive prices. By optimizing our production processes and supply chain management, we are able to provide cost - effective products without sacrificing quality.

5. Excellent Customer Service: Our customer service team is always ready to assist you. From pre - sales consultation to after - sales support, we are committed to providing you with prompt and professional service.

If you are interested in our BYC Ti Platinized Titanium Anode or have any questions regarding our products or services, please do not hesitate to contact us.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية