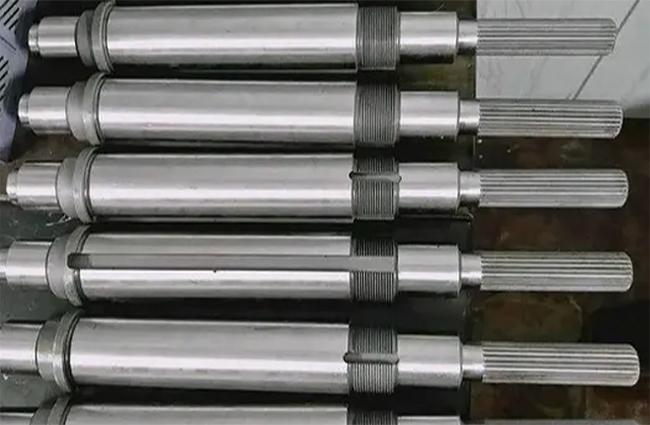

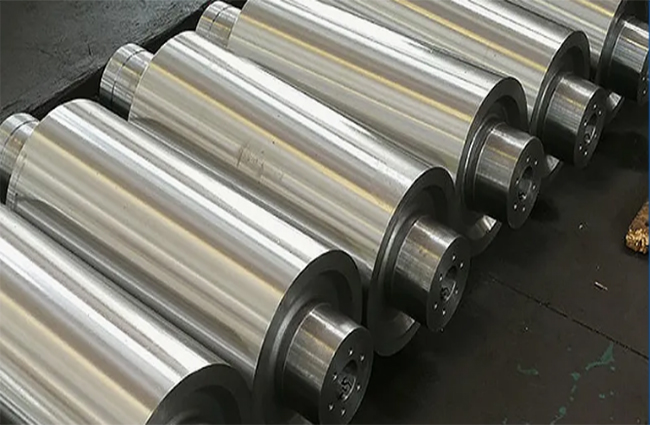

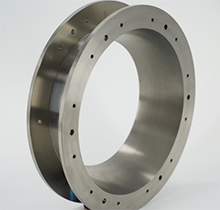

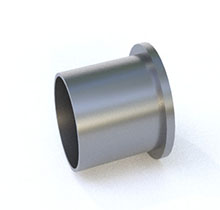

Titanium Shafts & Forged Shafts Main Features

· Material Grades: TA2, TA3, TA10, TC4 (Ti-6Al-4V), Ti-6246, Ti-6Al-7Nb

· Forging Type: Open die forging

· Length Range: 100 mm – 3000 mm

· Diameter Range: 20 mm – 300 mm

· Surface Finish: Turned, ground, polished or customized

· Standards: ASTM B381, AMS4928, ISO 5832-2

Titanium Shafts & Forged Shafts Applications

· Aerospace: Drive shafts, rotor shafts

· Marine: Propulsion shafts, rudder shafts

· Industrial: Pump shafts, transmission shafts

· Medical: Orthopedic rods and custom implants

· Energy: Shafts for offshore and deep-sea operations

BYC Ti Titanium Shafts & Forged Shafts Advantages

· Excellent strength and fatigue resistance

· Outstanding corrosion resistance in saltwater and chemical environments

· Tight dimensional control with CNC finishing

· Custom length, diameter, and surface finish available

· Full traceability and quality inspection reports

Custom Titanium Shafts & Forged Shafts Service

We provide precision titanium shaft forgings based on your application drawings and technical requirements. Whether for aerospace drive systems or marine propulsion, our forged shafts offer excellent performance and reliability.

Titanium Shafts & Forged Shafts Quality Control & Certification

Each forged titanium shaft undergoes:

- Ultrasonic Testing (UT)

- Chemical and Mechanical Testing

- Straightness and Dimension Inspection

- Third-party inspection available upon request

Certificates: EN 10204 3.1 / 3.2, ISO 9001, AS9100

Send us your specifications for a prompt quote. We deliver consistent quality and fast lead times.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية