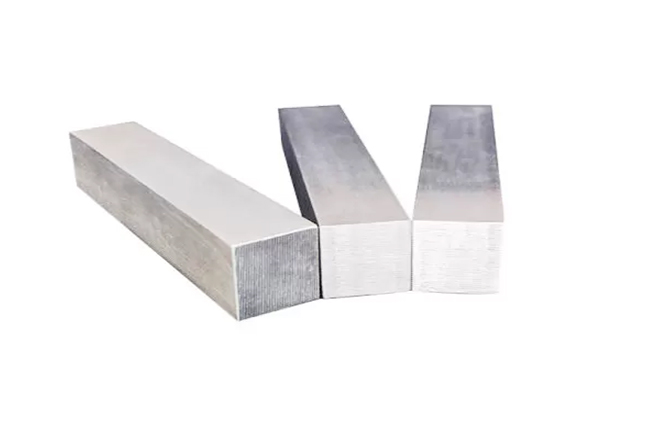

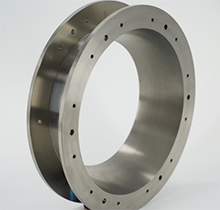

Titanium Billets / Forged Blocks Main Features

* Material Grades: TA1, TA2, TA3, TA10, TC4 (Ti-6Al-4V), Ti-6242, Ti-6Al-7Nb

* Forging Type: Open die forging

* Length Range: 100 mm – 2000 mm

* Width/Height Range: 30 mm – 500 mm

* Surface Finish: Rough machined, turned, or as-forged

* Standards: ASTM B381, AMS4928, ISO 5832-2

Titanium Billets / Forged Blocks Applications

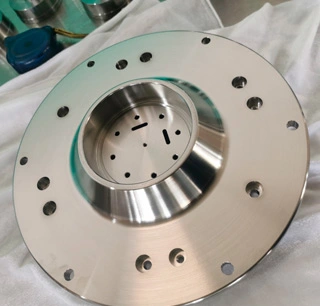

* Aerospace: Structural components, aircraft base plates

* Medical: Orthopedic implants and machining stock

* Marine: Subsea support blocks, structural elements

* Industrial: CNC machined components, mold bases

* Energy: Offshore and oilfield equipment

BYC Ti Titanium Billets / Forged Blocks Advantages

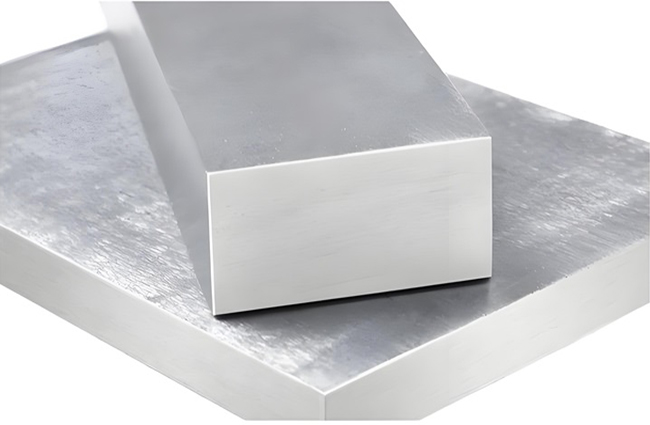

* Excellent strength and structural integrity

* Uniform grain flow and high purity

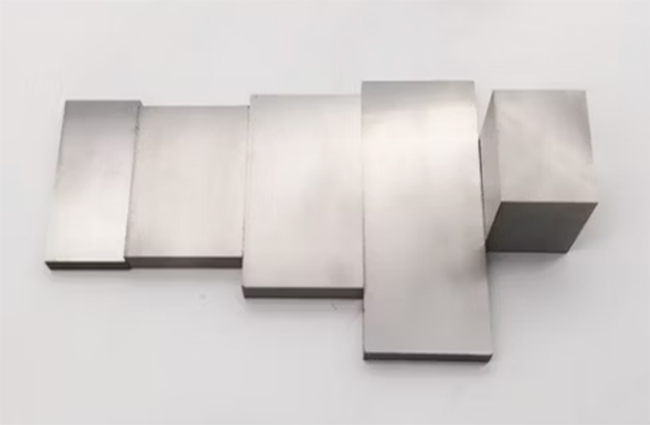

* Custom sizes available to reduce machining waste

* Corrosion resistance in aggressive environments

* Available with full mill test and third-party inspection

Custom Titanium Billets/Forged Blocks Service

We provide precision-forged titanium blocks and billets tailored to your exact specifications. Whether you need large slabs for machining or near-net shape billets, our forging and heat treatment process ensures consistent quality.

Titanium Billets & Forged Blocks Quality Control & Certification

Each forged titanium block and billet undergoes:

* Ultrasonic Testing (UT)

* Mechanical and Chemical Testing

* Dimensional and Flatness Inspection

* Third-party inspection on request

Certificates: EN 10204 3.1 / 3.2, ISO 9001, AS9100

Send your drawing or size requirements to get a fast quote. We ensure quality and quick delivery.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية