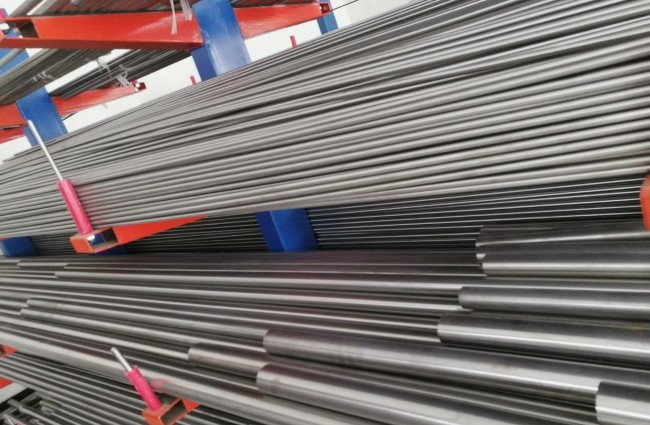

Titanium Round Bar Technical Specifications

Parameter | Specification | Notes |

Diameter Range | 6mm – 300mm | Custom diameters available |

Length Range | ≤6000mm | Cut-to-size service available |

Grades Available | GR1, GR2, GR5, GR9, GR23 | ASTM B348 / AMS / ISO standards |

Surface Finish | Turned, Polished, Peeled

| Mirror polish on request

|

Tolerance | h9–h11 | As per customer drawings

|

Density | 4.51 g/cm³ | Lightweight

|

Melting Point | ~1660°C | High-temp performance

|

Titanium Round Bar Applications

Titanium Round Bar in Aerospace

Titanium round bars are integral to aerospace applications, serving as robust structural rods for aircraft. They are critical in constructing engine and frame components, offering exceptional strength-to-weight ratios and resistance to extreme temperatures, ensuring reliability in demanding flight conditions.

Titanium Round Bar in Medical

In the medical field, titanium round bars are utilized for crafting durable implants. Their biocompatibility makes them ideal for orthopedic and dental applications, providing long-lasting solutions for bone fixation and dental prosthetics with minimal risk of rejection.

Titanium Round Bar in Marine & Chemical

Titanium round bars excel in marine and chemical environments, used in shafting, fasteners, and heat exchangers. Their superior corrosion resistance makes them perfect for chlorine and saltwater systems, ensuring durability in harsh, corrosive conditions.

Titanium Round Bar in Industrial Engineering

In industrial engineering, titanium round bars are employed in high-performance fixtures and corrosion-resistant frameworks. Their strength and durability support heavy-duty applications, maintaining structural integrity in challenging industrial settings.

Titanium Round Bar in Manufacturing Excellence

Titanium round bars are precision-forged and heat-treated from premium titanium billets to ensure top-tier quality. Advanced CNC machining guarantees tight tolerances and consistent roundness, meeting stringent industry standards. Each bar undergoes rigorous ultrasonic testing and verification of mechanical and chemical properties to ensure performance reliability. A 3.1 Inspection Certificate (EN10204) is available upon request to validate quality compliance.

Titanium Round Bar in Packaging & Logistics

Titanium round bars are packaged with care, sealed in moisture-proof plastic and housed in fumigation-free wooden crates to ensure product integrity during transport. Suitable for sea, land, and air freight, the bars are custom-palletized with size labeling for enhanced traceability, streamlining logistics and delivery processes.

Why Choose BYC Ti Titanium Round Bar for Sale?

BYC Ti, with over 20 years of expertise, offers high-quality titanium round bars tailored to diverse industries. Our titanium round bars for sale deliver exceptional value at competitive titanium round bar prices.

Exceptional Properties of BYC Ti Titanium Round Bars

Our 6al 4v titanium round bar is 45% lighter than steel with equal strength, ideal for weight-sensitive applications. It resists corrosion from acids, seawater, and chlorine, and withstands temperatures up to 600°C, perfect for aerospace and energy sectors. Grade 23 bars are biocompatible for medical use, while non-magnetic, non-toxic properties suit electronics and cleanrooms. ISO 9001 and AS9100 certifications ensure reliable quality.

Comprehensive Customization Options

We offer custom titanium alloy round bar stock in specific lengths, diameters, and alloy grades like Ti6242 or Ti-5553. OEM markings and color coding ease integration. Our R&D and global delivery ensure innovative solutions and fast shipping at competitive titanium round bar prices. Contact us to explore titanium round bars for sale!

Titanium Round Bar FAQs

Q: Can titanium round bars be used for CNC precision machining?

A: Yes, all bars are precision-forged and suitable for high-speed machining with minimal tool wear.

Q: Which grade is best for medical applications?

A: Grade 23 (Ti-6Al-4V ELI) is ideal due to its biocompatibility and excellent fatigue strength.

Q: Are small quantity orders accepted?

A: Yes, we support both prototype and volume production runs.

Q: How long is the lead time?

A: Standard sizes are available within 5–7 working days. Custom sizes may require 2–3 weeks.

Ready to source premium titanium round bars? Contact our materials specialist for a tailored quote and technical consultation.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية