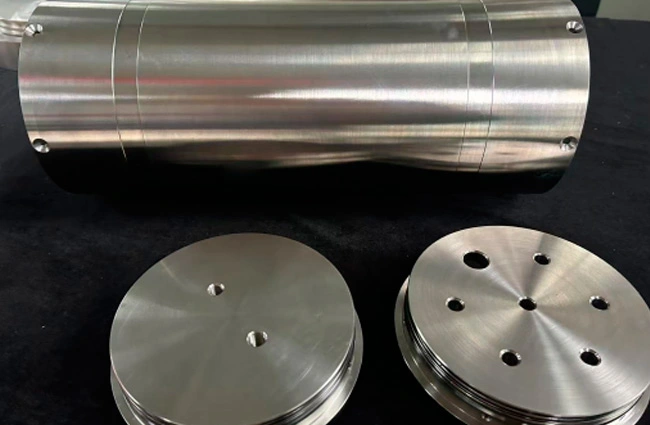

Application of Titanium Alloy Battery Chamber

Aerospace

Automotive Industry

Consumer Electronics

Medical Devices

Military and Defense

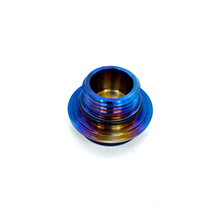

Machinability of Titanium Alloy Battery Chamber

High-Speed Machining (HSM):

High-speed machining techniques can be employed with appropriate adjustments to cutting parameters to improve efficiency and surface finish.

Cryogenic Machining:

Using liquid nitrogen as a coolant can significantly reduce tool wear and improve surface finish by maintaining low temperatures at the cutting zone.

Electrical Discharge Machining (EDM):

For complex shapes and hard-to-machine areas, EDM can be used to achieve precise cuts without direct contact between the tool and workpiece.

Additive Manufacturing:

In some cases, additive manufacturing techniques such as selective laser melting (SLM) can be used to create near-net-shape titanium alloy components, reducing the need for extensive machining.

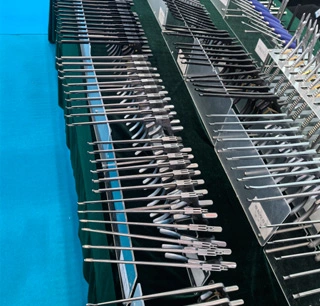

To meet the high standards of these demanding applications, we, as a specialized CNC machining titanium supplier, utilize advanced cnc machining titanium techniques, which ensure the precision and durability required for titanium alloy battery chambers across various industries.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية