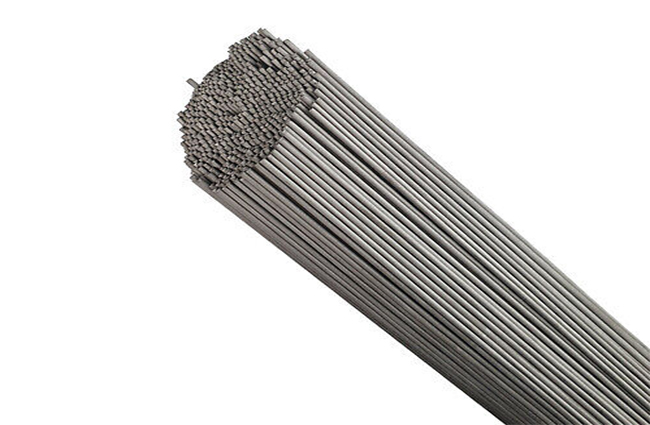

Titanium TIG Welding Rod Product Highlights

Commercially Pure & Alloy Grades: CP1–CP4, Ti-6Al-4V, Ti-3Al-2.5V, ELI variants

Precision Cut Lengths: 914 mm (36") standard; custom lengths available

Straightness:<1 mm deviation per meter

Surface Finish: Polished, oxide-free, degreased, weld-ready

Packaging: Vacuum-sealed in inert gas or foil, 5 kg tubes or 10 kg boxes

Certifications: AWS A5.16, ASTM B863, ISO 5832, AMS specs available

Titanium TIG Welding Rod Applications

Aerospace component welding

Chemical plant piping & tank fabrication

Offshore and shipyard structural welding

Heat exchangers, valves, and titanium fittings

Medical device welding (for ELI grades)

Maintenance of titanium process equipment

Titanium TIG Welding Rod Common Grades & Use Cases

Grade | Description | Typical Applications |

CP Grade 1 | Softest, highest ductility | Heat exchangers, medical welds |

CP Grade 2 | Balanced strength/formability | Marine systems, tanks, pressure vessels |

Ti-3Al-2.5V | Medium-strength alloy | Tubing, aircraft hydraulic systems |

Ti-6Al-4V (Grade 5) | High-strength alloy | Aerospace, motorsports, offshore structures |

Ti-6Al-4V ELI | Extra low interstitials | Biomedical, cryogenic applications |

Titanium TIG Welding Rod Technical Data (Typical)

Property | Value Range |

Rod Diameter | 1.6 mm – 5.0 mm |

Length | 914 mm (36") or custom |

Tolerance | Diameter: ±0.05 mm; Length: ±1 mm |

Tensile Strength | 240–950 MPa (grade dependent) |

Cleaning Method | Ultrasonic + Vacuum Packaged |

Weld Compatibility | GTAW (TIG), PAW (Plasma Arc) |

Certifications | AWS, ASTM, ISO, NADCAP ready |

Why Choose BYC Ti Titanium TIG Welding Rod?

No Weld Failures: Clean chemistry, no internal porosity or inclusions

Stable Arc Performance: Predictable puddle, low spatter, excellent wetting

Consistent Batches: Strict QC, every rod traceable to heat lot

Packaged for Purity: No oxide, no fingerprints, no surprises

Whether in a Class 100 cleanroom or an offshore welding tent, our rods deliver consistent results across every joint.

Titanium TIG Welding Rod FAQ – Frequently Asked Questions

Q: Are these rods suitable for automated welding systems?

A: No. These are manual feed rods for TIG and plasma welding. For wire-fed automation, see our Titanium Welding Wire product.

Q: Do you offer customized rod diameters or lengths?

A: Yes. Standard is 1.6 mm × 914 mm, but we can supply rods from 1.0 to 6.0 mm in diameter and custom lengths upon request.

Q: What's the difference between CP Grade 2 and Ti-6Al-4V rods?

A: Grade 2 offers better formability and corrosion resistance, while Ti-6Al-4V offers higher strength for load-bearing welds.

Q: How are your rods cleaned and packaged?

A: All rods are degreased, ultrasonically cleaned, and vacuum-sealed in argon or nitrogen to prevent oxidation.

Q: Are these rods export certified?

A: Yes. We comply with AWS, ASTM, and aerospace/medical export standards.

Titanium TIG Welding Rod Ordering & Support

MOQ: 5 kg (sample), bulk up to 2 tons/month

Delivery: 7–14 working days, global shipping available

Custom Grades: Yes — including medical, marine, and defense alloys

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية