Titanium and titanium alloys are widely recognized for their unique combination of strength, corrosion resistance, and light weight. While both materials offer excellent performance across a range of demanding applications, there are key differences in their composition, properties, and industrial uses. Understanding these distinctions is essential for choosing the right material for aerospace, medical, chemical, and industrial applications.

What Is Titanium?

Pure titanium is a lustrous, silver-gray metal known for its high strength-to-weight ratio and excellent corrosion resistance. It is categorized into grades such as Grade 1 to Grade 4, depending on oxygen and impurity content. Commercially pure titanium is non-toxic, biocompatible, and ideal for applications requiring moderate strength and high corrosion resistance.

Key properties of pure titanium:

High corrosion resistance (especially in seawater and chloride environments)

Excellent biocompatibility (ideal for medical implants)

Low density (about 4.51 g/cm³)

Melting point around 1,668°C

Common uses of pure titanium:

What Are Titanium Alloys?

Titanium alloys are created by combining titanium with elements such as aluminum, vanadium, molybdenum, or zirconium. These alloying elements improve strength, heat resistance, and formability, making titanium alloys suitable for more demanding structural or high-temperature applications.

The most widely used titanium alloy is Ti-6Al-4V (Grade 5), containing 6% aluminum and 4% vanadium. This alloy offers a superior balance of strength, corrosion resistance, and workability.

Key properties of titanium alloys:

Higher tensile strength compared to pure titanium

Greater fatigue and crack resistance

Improved machinability and weldability (varies by grade)

Suitable for high-performance engineering applications

Common uses of titanium alloys:

Aerospace components (jet engines, airframes, fasteners)

Automotive and motorsports parts

3D printing of structural and custom components

Industrial tooling and chemical processing equipment

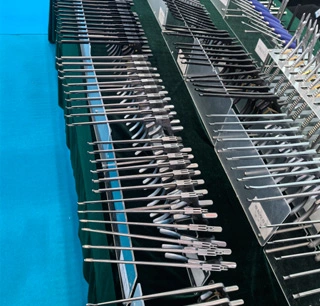

Surgical instruments and orthopedic devices

Key Differences Between Titanium and Titanium Alloys

| Property | Pure Titanium | Titanium Alloys |

|---|

| Strength | Moderate | Higher (especially Grade 5 / Ti-6Al-4V) |

| Corrosion Resistance | Excellent | Very good, varies by alloy |

| Biocompatibility | Superior | Very good, some alloys suitable for medical use |

| Applications | Chemical, medical, marine | Aerospace, 3D printing, industrial |

| Cost | Generally lower | Slightly higher due to alloying |

How to Choose Between Titanium and Titanium Alloys?

Choose pure titanium when corrosion resistance, biocompatibility, or low weight is more critical than strength.

Choose titanium alloys when high strength, heat resistance, or fatigue performance is required—such as in aerospace, defense, or additive manufacturing.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية