Titanium wire, as the name suggests, is a type of titanium material that not only possesses all the characteristics of titanium metal but also has the toughness and flexibility of filamentous material. It is used in many fields.

Performance of Titanium Wire

The density of titanium metal is 4.54g/cm³, 43% lighter than steel, and slightly heavier than magnesium. Light weight is an important characteristic that allows titanium wire to be used in various fields. Titanium wire has excellent strength and toughness, especially in extreme environments of high temperature and high pressure, where it demonstrates its advantage. Titanium wire also boasts outstanding corrosion resistance and biocompatibility. Whether in highly corrosive external environments or within the body's fluid environment, titanium wire performs excellently.

Applications of Titanium Wire

Titanium Welding Wire

Currently, most titanium wires are used as welding wires. Whether for underwater welding, laser filler wire welding, or in the aerospace, chemical, and biomedical fields, titanium welding wires are widely used. Before welding with titanium welding wire, steps like groove processing, cleaning the welding area, preheating before welding, and chemical treatment can effectively improve the welding quality.

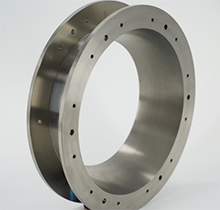

Titanium wire is characterized by its lightweight and high strength. Combined with the high-temperature resistance and non-magnetic properties of titanium metal itself, titanium wire can easily adapt to the relatively extreme environments in the aerospace field without being affected by various magnetic fields. Although titanium wire is expensive, the aerospace industry, known for its high barriers to entry, prioritizes safety and reliability. Therefore, titanium wire is widely used in the aerospace field, including in engine components, body structures, pipelines, and connectors.

The diameter of human hair is approximately between 0.06-0.09mm, and titanium wire used in the medical field can be as thin as 0.1mm. This means that a titanium wire can be almost as thin as hair while ensuring stable performance. The manufacturing process of titanium wire makes its application in the medical field possible, and its excellent corrosion resistance and biocompatibility ensure its safety. Titanium wire is mainly used in medicine to manufacture orthopedic implants, dental restorations, cardiovascular devices, and other medical equipment.

Titanium wire has excellent corrosion resistance, making it widely used in the chemical industry in applications like tower plates, distillation columns, reactors, and storage tanks.

With economic development and advancements in titanium wire manufacturing processes, the applications of titanium wire in daily life will become increasingly widespread. However, the high cost of titanium wire still poses a barrier to its application in many fields. Therefore, it is a misconception to pursue titanium wire blindly in material selection. The optimal use of titanium wire is achieved by considering comprehensive performance, technology, price, and other factors. Yuchenghai, as one of the professional titanium wire manufacturers, will be the best choice.

3D Printing Field

Titanium wire is widely used in directed energy deposition (DED) and other metal additive manufacturing processes, suitable for printing and repairing high-performance titanium alloy components. Compared to titanium powder, titanium wire has advantages such as higher purity, greater safety, and higher material utilization. It is often used in aerospace, medical device, and scientific research fields, particularly suitable for the rapid formation of large-sized structural parts.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية