Titanium, a lustrous and lightweight metal, has a remarkable set of properties that translate into highly effective bolts. One of the most compelling features is its exceptional strength-to-weight ratio. Compared to traditional metals like steel, titanium bolts can provide substantial strength while significantly reducing the overall weight of a structure. This is particularly crucial in industries such as aerospace and automotive, where minimizing weight is a constant pursuit to enhance fuel efficiency and performance.

Another standout property is its corrosion resistance. Titanium naturally forms a thin, protective oxide layer on its surface when exposed to air. This layer is not only stable but also self-healing, meaning that if it gets scratched or damaged, it can quickly reform in the presence of oxygen. As a result, titanium bolts are highly resistant to corrosion, even in harsh environments such as those with high humidity, saltwater, or exposure to chemicals. This makes them an ideal choice for applications in marine, offshore, and chemical processing industries.

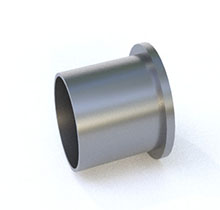

Grades Galore: Understanding the Spectrum of Titanium Bolts

Titanium bolts are available in various grades, each with its own set of characteristics tailored to specific applications.

Grade 2

Grade 2 titanium bolts are made from commercially pure titanium. They offer a good balance of strength, ductility, and corrosion resistance. This grade is the most commonly used for general-purpose applications. In industrial settings, they are often used in equipment where resistance to corrosion from mild chemicals and water is required. Their moderate strength makes them suitable for applications where the load-bearing requirements are not overly demanding, but the need for long-term durability in potentially corrosive environments is a priority.

Grade 5

Grade 5 titanium, also known as Ti-6Al-4V (an alloy containing 6% aluminum and 4% vanadium), is significantly stronger than Grade 2. It has an outstanding strength-to-weight ratio and excellent fatigue resistance. This grade is widely used in high-stress applications such as aerospace, military, and high-performance automotive. In aircraft manufacturing, Grade 5 titanium bolts are used to secure critical components, ensuring that they can withstand the extreme forces and vibrations experienced during flight. Their ability to maintain strength at elevated temperatures also makes them suitable for applications in engines and other high-temperature environments.

Grade 7

Grade 7 titanium bolts contain a small amount of palladium, which further enhances their corrosion resistance, especially in reducing environments. They are often used in applications where exposure to aggressive chemicals, such as certain acids, is a concern. In the chemical processing industry, Grade 7 bolts may be used in equipment handling corrosive substances, providing an extra layer of protection against degradation.

Applications Across Industries

The versatility of titanium bolts has led to their widespread use across multiple industries.

Aerospace

In the aerospace industry, every ounce of weight matters. Titanium bolts are used extensively in aircraft construction. They are used to fasten the fuselage, wings, and engine components. Their lightweight nature helps reduce the overall weight of the aircraft, leading to improved fuel efficiency and longer range. Additionally, their high strength and ability to withstand extreme temperatures and vibrations ensure the structural integrity of the aircraft under demanding flight conditions.

Automotive

In high-performance automotive applications, titanium bolts are used to replace heavier steel bolts. This reduces the unsprung weight of the vehicle, improving handling and acceleration. They are often used in suspension components, engine parts, and wheel assemblies. For example, in racing cars, where every bit of performance gain is crucial, titanium bolts can make a significant difference in the overall performance of the vehicle.

Marine

The marine environment is extremely corrosive, with saltwater and high humidity. Titanium bolts are highly resistant to this corrosion, making them ideal for use in boats, ships, and offshore structures. They are used to fasten hull components, deck fittings, and engine mounts. Their durability in saltwater environments ensures that marine vessels can operate for long periods without the need for frequent replacement of fasteners due to corrosion.

Medical

Titanium's biocompatibility makes it a preferred material for medical implants, and this extends to bolts used in orthopedic and dental applications. In orthopedics, titanium bolts may be used to secure bone plates or prosthetic joints. In dentistry, they can be used in dental implants. Their non-toxic and non-reactive nature means that they can be safely implanted in the human body, promoting long-term stability and functionality of the implants.

Selecting the Right Titanium Bolt

When choosing a titanium bolt for a specific application, several factors need to be considered.

Application Requirements

The first step is to assess the requirements of the application. Consider the load that the bolt will need to bear, the environmental conditions it will be exposed to (such as temperature, humidity, and chemical exposure), and any space or weight constraints. For high-stress applications, a higher-grade bolt like Grade 5 may be required. In a corrosive marine environment, a bolt with excellent corrosion resistance, such as Grade 2 or Grade 7, would be more suitable.

Size and Thread Specifications

Selecting the correct size and thread type is crucial. The bolt needs to fit properly in the mating components and provide a secure fastening. Different applications may require specific thread pitches and diameters. For example, in precision machinery, a fine-threaded bolt may be needed for a more precise and secure connection, while in a large-scale construction application, a coarser thread may be more appropriate.

Quality and Supplier Reputation

It's essential to source titanium bolts from a reputable supplier. High-quality bolts are manufactured to strict standards, ensuring consistent performance. Look for suppliers who can provide documentation of the bolt's composition, mechanical properties, and compliance with relevant industry standards. A reliable supplier will also offer technical support and assistance in selecting the right bolt for your application.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية