Titanium alloys are widely used in fields such as aerospace, medical, automotive, and marine engineering due to their excellent properties, such as high strength, light weight, corrosion resistance, and high-temperature stability. With technological advancements, the processing methods of titanium alloys have become increasingly refined, particularly with the help of CNC (Computer Numerical Control) machining technology. The production of titanium alloy parts has become more efficient and precise.

CNC Titanium Parts

CNC (Computer Numerical Control) machining technology is a technique that uses computer programs to control machine tools for precision machining. It can produce parts with complex geometries and very high precision. The manufacturing process of CNC titanium parts typically includes the following steps:

Material Selection and Preparation

First, appropriate titanium alloy materials need to be selected. Commonly used titanium alloys include Ti-6Al-4V, Ti-5Al-2.5Sn, etc. These alloys not only have excellent mechanical properties but also meet the high requirements for parts in aerospace, medical, and other fields. The preparation of titanium alloys includes cutting the raw material blocks into suitable sizes for subsequent processing.

CNC Programming

The core of CNC machining lies in programming. Programmers need to use CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to generate machining paths suitable for CNC machine tools based on the part's design drawings. The machining of titanium alloys requires high precision, so programmers need to ensure that every detail is considered, such as the tool path, cutting speed, and feed rate.

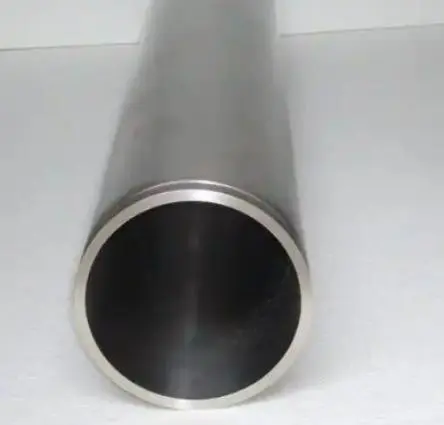

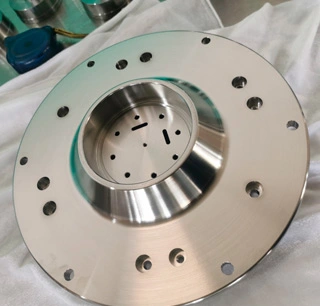

CNC Machining

Once the CNC programming is completed, the parts enter the CNC machine tool for processing. Due to the high strength of titanium alloys, the cutting forces are large, and the temperature tends to rise. Therefore, appropriate cutting tools and coolants need to be used during CNC machining to reduce tool wear and ensure machining accuracy. CNC machining includes milling, turning, drilling, grinding, and other processes, enabling the precise manufacture of complex titanium alloy parts.

Post-Processing

After machining, titanium alloy parts usually need to undergo some post-processing steps to improve their surface quality and performance. Common post-processing techniques include sandblasting, polishing, anodizing, etc. These processes can not only improve the appearance of the parts but also enhance their corrosion resistance and wear resistance.

Advantages of CNC Titanium Parts

High Precision and Complex Shapes

CNC machining technology can achieve very high machining precision and manufacture extremely complex titanium alloy parts. This is crucial for components requiring precise dimensions and complex geometries, especially in the aerospace and medical fields.

High Production Efficiency

Although machining titanium alloys is more difficult compared to other materials, the high degree of automation in CNC technology can significantly improve production efficiency. Once programming is completed, the machine tool can perform long-term continuous machining, reducing manual intervention and production time.

High Material Utilization

CNC machining technology uses precise cutting methods, effectively reducing material waste. In the manufacture of high-value titanium alloy parts, reducing material loss is very important. This not only lowers costs but also increases production efficiency.

Strong Adaptability

CNC machining technology is suitable for titanium alloy parts of various shapes and sizes. Whether for small batch production or custom single-piece production, the program can be adjusted flexibly. Additionally, CNC machining technology can meet highly customized demands, particularly in industries with strict requirements such as aerospace and medical equipment.

Conclusion

With the development of CNC machining technology, the processing of titanium alloys has become more efficient and precise, driving the growing demand for titanium alloy parts in various industries. From aerospace to medical, automotive, and marine engineering, CNC titanium parts can meet the requirements of high strength, light weight, and corrosion resistance while being highly customizable according to different application needs. With continuous technological advancements, the manufacturing process of CNC titanium parts will be further optimized, promoting innovation and development across various industries.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية