Product Features

1. High Electrocatalytic ActivityThe unique chemical properties of ruthenium endow the anode with outstanding electrocatalytic performance, significantly reducing the overpotential of reactions such as chlorine evolution and oxygen evolution. In the electrolysis process, it facilitates reactions, greatly improving electrochemical conversion efficiency and boosting high-efficiency operations in various industrial productions.

2. Superior Corrosion ResistanceWhen facing complex and corrosive electrolyte environments, such as strong acids, alkalis, or high-concentration salt solutions, the ruthenium coating and titanium substrate work in synergy to form a robust protective barrier. In 98℃ concentrated sulfuric acid solution, its corrosion rate is only 1/50 of that of ordinary titanium anodes, effectively resisting the erosion of corrosive ions like chloride ions. This ensures the anode operates stably for a long time in harsh conditions and significantly extends its service life.

3. Excellent Dimensional StabilityDuring long-term electrolysis, the anode maintains stable dimensions, and the electrode spacing does not change. This feature is crucial for maintaining the stability and consistency of electrolysis operations, effectively reducing energy consumption fluctuations caused by electrode dimension changes and ensuring efficient and stable production processes.

4. Good Electrical ConductivityBy doping nanocarbon materials (such as graphene), the coating resistivity is reduced from 15Ω·cm in traditional processes to 5Ω·cm. The unique microstructure forms an efficient electron transport channel, ensuring uniform and rapid current passage through the anode, reducing resistance loss, and improving power utilization efficiency.

Product Advantages

1. Energy Saving and Consumption ReductionCompared with traditional anode materials, BYC Ti's ruthenium-coated titanium anode can operate at a lower cell voltage due to its low overpotential and good electrical conductivity, significantly reducing energy consumption in the electrolysis process. In large-scale electrolysis applications such as the chlor-alkali industry, it helps enterprises effectively cut power costs and enhance economic benefits.

2. Long Service LifeThe excellent corrosion resistance and stable structural design significantly extend the anode's service life, which can reach more than 8 years in the chlor-alkali industry. The long life not only reduces downtime and labor costs caused by frequent electrode replacement but also decreases waste generation, aligning with the concept of sustainable development.

3. Environmental Protection and No PollutionDuring electrolysis, the anode does not release harmful metal ions into the electrolyte, avoiding pollution to the environment and products. It is particularly suitable for industries with high requirements for product purity and the environment, such as electrochemical applications in food processing and pharmaceuticals.

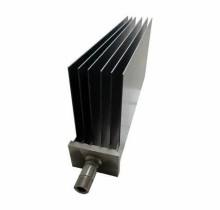

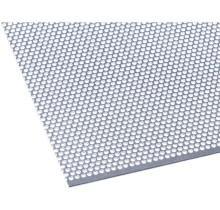

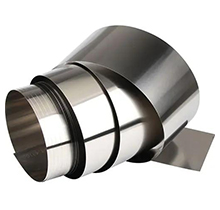

4. Customized ServicesWe understand that different customers have diverse application scenarios and requirements, so we provide comprehensive customized services. We can customize the anode's size, shape (such as plate, mesh, tubular, etc.), and coating thickness and composition according to customers' actual working conditions, ensuring the product perfectly adapts to various complex working conditions.

Technical Parameters

1. Substrate MaterialHigh-purity TA1/TA2 titanium with a purity ≥99.5% is selected, ensuring the anode has a good foundation of mechanical properties and corrosion resistance.

2. Coating MaterialMainly ruthenium oxide (RuO₂), and appropriate other elements (such as iridium) can be added as needed to form a multi-element coating to optimize the anode performance.

3. Coating Thickness5 - 20μm. The coating thickness is precisely controlled to ensure the anode has high catalytic activity while maintaining stable structure and long life.

4. Applicable EnvironmentSuitable for various electrolyte systems, including but not limited to sulfuric acid, hydrochloric acid, chloride systems, as well as various oxygen evolution and chlorine evolution environments.

5. Current Density≤3500A/m², which can work stably at high current densities to meet the needs of different production scales.

Application Fields

1. Chlor-Alkali IndustryAs the anode of chlor-alkali electrolyzers, it efficiently promotes the oxidation of chloride ions to generate chlorine. Meanwhile, with the characteristics of low energy consumption and long life, it provides strong support for the stable and efficient operation of chlor-alkali production.

2. Electroplating IndustryUsed as an insoluble anode in various electroplating processes such as galvanizing, nickel plating, copper plating, and chrome plating. It can provide stable current, ensure uniform and dense coatings, improve the quality of electroplated products, and reduce electrode loss costs in the electroplating process.

3. Wastewater TreatmentUsing the anodic electrocatalytic oxidation effect, it degrades organic pollutants, ammonia nitrogen, and other harmful substances in wastewater, effectively improving the biodegradability of wastewater to achieve water purification. It performs excellently in treating electroplating wastewater, printing and dyeing wastewater, landfill leachate, etc., and can significantly reduce pollutant emission concentrations.

4. Seawater Desalination and Seawater Chlorine ExtractionIn seawater desalination, it is used in the cathodic protection system to prevent equipment corrosion; in seawater chlorine extraction processes, it efficiently electrolyzes seawater to produce chlorine for disinfection and sterilization. Its seawater corrosion resistance ensures long-term stable operation in marine environments.

5. Other FieldsWidely used in many electrochemical fields requiring efficient and stable anodes, such as water electrolysis for hydrogen production, electrolytic copper foil production, swimming pool water disinfection, and ionized water electrolysis.

Product Services

1. Pre-Sales ServiceA professional technical team provides customers with detailed product consultations and technical solution designs. According to customers' needs and application scenarios, we recommend the most suitable product models and specifications and offer customized suggestions.

2. In-Sales ServiceWe strictly produce and deliver goods according to the time and quality standards stipulated in the contract, and timely feedback the order progress to customers to ensure they receive the products on time.

3. After-Sales ServiceProvide comprehensive after-sales technical support, including on-site installation guidance, debugging services, and operation training, to ensure customers can use the product correctly. Meanwhile, establish a long-term customer mechanism (customer return visit mechanism) to promptly solve problems encountered by customers during use. If product quality problems occur, we will respond and provide solutions within the shortest time to ensure customers' production is not affected.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية