Product Features

1. Extreme Electrochemical StabilityIridium oxide coatings exhibit superior resistance to anodic dissolution, maintaining integrity even at high potentials (up to 2.5V vs. SCE). This stability ensures consistent performance in demanding processes like oxygen evolution, where other materials may degrade rapidly.

2. Ultra-Low Corrosion RateIn concentrated sulfuric acid (98% H₂SO₄) at 90°C, the corrosion rate measures <0.01 mm/year—50 times lower than traditional platinum-coated anodes. The dense iridium oxide layer forms a passive barrier against chloride ions, making it ideal for seawater and brine-based systems.

3. Nanostructured Coating TechnologyOur proprietary sol-gel process creates a nano-porous coating with a specific surface area of 25 m²/g, doubling the active site density compared to conventional methods. This microstructure enhances electrocatalytic activity for reactions like water oxidation.

4. Thermal Shock ResistanceThe anode withstands rapid temperature fluctuations (20°C to 150°C) without delamination, thanks to optimized coating-substrate adhesion (bond strength >50 MPa). This feature ensures reliability in intermittent operation or process upsets.

Product Advantages

1. Extended Service LifeIn chlor-alkali electrolysis at 4 kA/m², the anode lasts over 10 years—30% longer than industry averages. The reduced need for replacement minimizes downtime and maintenance costs, delivering total cost of ownership savings of up to 40%.

2. Energy EfficiencyThe low overpotential for oxygen evolution (≤250 mV at 1 kA/m²) translates to lower cell voltages. In an electrolytic hydrogen production plant, this results in a 12% reduction in specific energy consumption, saving $0.15/kg H₂ at scale.

3. Environmental ComplianceFree from heavy metal leaching (Cr⁶⁺ < 0.1 ppm), the anode meets strict environmental regulations for wastewater treatment applications. Its inertness ensures no contamination of treated effluents, ideal for potable water and food-grade processes.

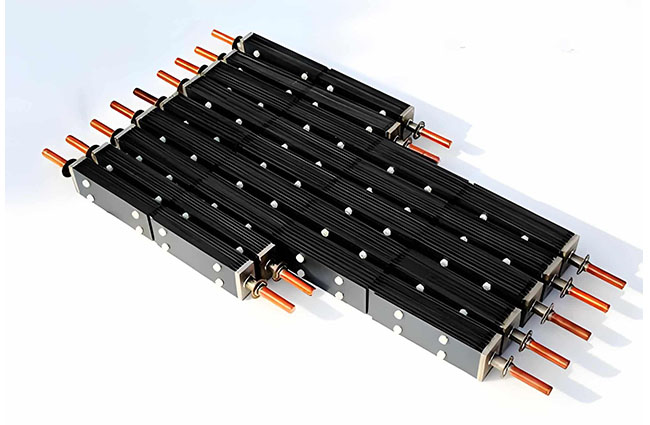

4. Custom EngineeringTailored solutions include:

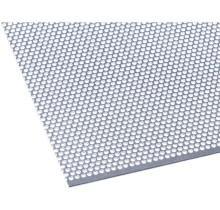

• Mesh configurations for high mass transfer (void fraction up to 60%)

• Tubular designs for circular cell geometries

• Graded coatings (IrO₂-Ta₂O₅) for mixed acid environments

Technical Parameters

Parameter | Value |

Substrate Material | TA2 Titanium (99.6% purity) |

Coating Composition | IrO₂ (90%) + Ta₂O₅ (10%) |

Coating Thickness | 8 - 15 μm (uniformity ±10%) |

Operating Temperature | -20°C to 180°C |

Maximum Current Density | 5000 A/m² (continuous) |

Electrical Resistivity | < 8 Ω·cm |

Application Fields

1. Hydrogen ProductionAs the oxygen-evolving anode in PEM electrolyzers, achieving >99.999% purity H₂ with low energy input. Installed in a 10 MW plant, our anode enables 2.3 tons/day H₂ production at 4.2 kWh/Nm³.

2. Metal FinishingIn hard chrome plating baths (600 g/L H₂SO₄), the anode maintains stable operation without chromium deposition, ensuring consistent coating thickness (25 - 50 μm) and brightness (ASTM B449 grade A).

3. Pharmaceutical ElectrosynthesisUsed in the anodic oxidation of organic intermediates, providing precise potential control (±5 mV) for selective synthesis. Featured in the production of active pharmaceutical ingredients (APIs) with >98% yield.

4. Marine Cathodic ProtectionDeployed in offshore platforms, the anode delivers uniform current distribution (±3% over 100 m²) in seawater (3.5% salinity), protecting steel structures from corrosion with a service life exceeding 15 years.

Product Services

1. Material Characterization ReportsEach anode shipment includes:

• SEM/EDX analysis of coating morphology

• XRD phase composition verification

• Polarization curve testing data (0 - 3 V vs. Ag/AgCl)

2. On-Site Process OptimizationOur engineers provide:

• Electrochemical impedance spectroscopy (EIS) mapping of cell performance

• Anode-cathode gap optimization for uniform current distribution

• Post-installation performance monitoring via remote data logging

3. Recycling ProgramAt end-of-life, we offer a closed-loop recycling service, recovering >95% of iridium for reuse. This program reduces raw material costs by 30% for repeat customers while minimizing environmental impact.

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  русский

русский  العربية

العربية