Why Choose Titanium Flanged Hex Head Bolts?

· Rust-Proof and Reliable

Titanium offers excellent resistance to corrosion, even in saltwater and chemical environments.

· Stronger, Yet Lighter

High strength-to-weight ratio makes it ideal for applications where both performance and weight matter.

· Built-In Flange for Better Grip

The integrated flange provides a larger bearing surface, helping to spread the load and reduce damage to parts

· Clean, Professional Look

Smooth finish and hex head design ensure a neat appearance and easy installation.

· Made to Fit Your Needs

We support custom sizes, head types, and surface treatments — perfect for OEM or special projects

Technical Specifications of Titanium Flanged Hex Head Bolt

Specification | Details |

Material | Grade 2 or Grade 5 Titanium (custom options available) |

Size Range | M3 to M20 (custom sizes upon request) |

Thread Type | Metric (M), UNC, UNF (as per requirements) |

Head Type | Flanged Hex Head for better load distribution |

Finish | Polished, Natural, or Anodized |

Strength | High tensile strength, ideal for demanding applications |

Corrosion Resistance | Excellent resistance to rust, chemicals, and seawater |

Standard | DIN 912, ISO 4762, ASTM F136, MIL-DTL-46077 |

MOQ | Flexible for both sample and bulk orders |

Applications of Titanium Flanged Hex Head Bolt

Marine & Engineering

Connection parts of offshore platforms,

diving equipment, ships (resistant to seawater corrosion)

Chemical Industry

reactors, pipelines, heat exchangers

(in environments with corrosive media such as strong acids and alkalis)

Automotive Industry

engines, chassis

Medical Equipment

Connecting artificial joints, orthopedic fixation devices

(due to biocompatibility and corrosion resistance)

Energy Industry

For fastening various equipment

(high temperature and high pressure environments)

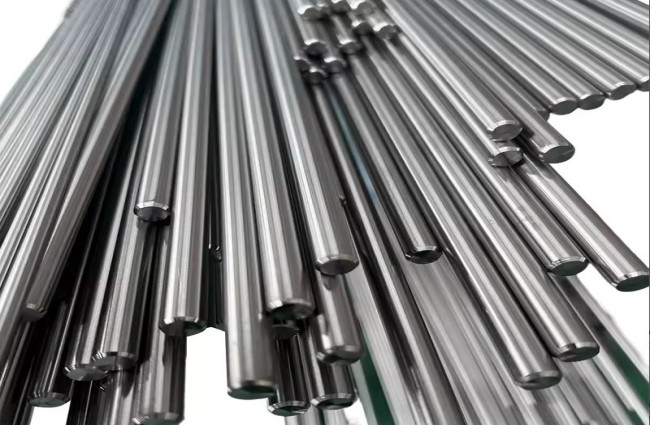

Manufacturing& Quality Assurance

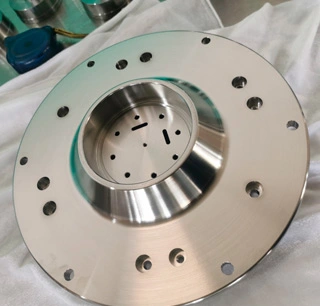

Precision CNC Machining – Ensures tight tolerances (±0.01mm).

Thread Rolling – Enhances fatigue resistance.

Heat Treatment – Optimizes mechanical properties.

Surface Finishing – Polished, anodized, or DLC-coated for durability.

100% Inspection – X-ray, and ultrasonic testing.

Why Partner With Us?

ISO 9001 certified – Aerospace-grade quality.

Full material traceability – Mill test certificates provided.

Custom configurations – Special sizes, coatings, and threading.

Fast global shipping – Stocked in multiple sizes for quick delivery.

Request a Quote

Looking for custom sizes or bulk orders? Reach out to us today!

Our team will provide you with detailed product information,

pricing, and lead times. Get a response in 24 hours!