Why Choose Titanium Hex Head Bolts?

When reliability matters most, our titanium hex bolts outperform conventional fasteners with:

45% lighter than steel with comparable strength

Complete corrosion resistance in saltwater and chemical environments

Non-magnetic properties for sensitive electronic applications

Biocompatible (ASTM F136 compliant for medical uses)

High-temperature stability (up to 600°F/315°C continuous service)

Technical Specifications

Parameter | Specification | Notes |

Size Range | M2 to M36 | Custom sizes available |

Length Range | 6mm to 300mm | Longer lengths by request |

Thread Standards | ISO, DIN, ANSI, JIS | UNC/UNF/Metric |

Surface Finish | Passivated, Anodized, Bead Blasted | Color anodizing optional |

Temperature Range | -250°C to +600°C | Varies by grade |

Corrosion Resistance | Excellent in:

• Saltwater

• Chlorine

• Acids

• Alkalis | Grade 7 best for acids |

Industry-Specific Applications

Aerospace & Defense

Aircraft structural components

Engine mounting hardware

Avionics enclosures

Satellite assemblies

Marine & Offshore

Saltwater-resistant boat hardware

Subsea equipment fasteners

Offshore platform components

Desalination plant fixtures

Industrial & Chemical

Corrosive environment piping

Semiconductor equipment

Pharmaceutical processing

Power generation systems

Medical Technology

MRI-compatible equipment

Surgical device assemblies

Diagnostic machine frames

Biocompatible implants

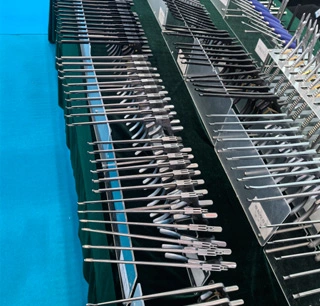

Manufacturing Excellence

Our titanium bolts undergo rigorous production:

Precision CNC Machining from certified titanium billets

Thread Rolling for superior fatigue resistance

Heat Treatment to optimize mechanical properties

Surface Finishing (passivation or anodizing)

100% Quality Inspection including:

Dimensional verification

Mechanical testing

Customization Options

Special thread forms (ACME, buttress)

Custom head markings

Proprietary coatings

Kitting and packaging

Laser engraving for traceability

Why Partner With Us?

20+ years titanium fastener expertise

ISO 9001 certified

Just-in-time inventory programs

Engineering support for special applications

Contact our fastener specialists to discuss your specific titanium bolt requirements.

Frequently Asked Questions

Q: How do titanium bolts compare to stainless steel?

A: Titanium offers equal strength at 45% less weight, with far superior corrosion resistance - especially in saltwater environments.

Q: Are these bolts reusable?

A: Yes, when properly torqued and maintained, our titanium hex bolts can be safely reused multiple times.

Q: What tools are needed for installation?

A: Standard hex wrenches or sockets. We recommend using anti-seize compound for best results.

Q: Do you offer custom sizes?

A: Absolutely! We regularly produce special diameters, lengths, and thread configurations.

Ordering Information

Standard items ship within 3-5 business days

Custom orders typically 2-4 week lead time

Competitive pricing for volume purchases

Worldwide shipping available