Why Choose Titanium Countersunk Bolt?

Titanium countersunk bolts are widely used for their strength, clean look, and corrosion resistance. Here are five reasons to choose them:

1. Smooth Surface Fit

The flat head allows the bolt to sit flush with the surface, ideal for designs that require a clean and low-profile finish.

2. Strong Against Corrosion

Titanium performs well in tough environments like marine and chemical industries. It resists rust and keeps stable over time.

3. Light but Strong

Though much lighter than steel, titanium still offers excellent strength, making it perfect for weight-sensitive uses.

4. Custom Options Available

OEM and ODM services are supported. You can customize size, thread, and surface to meet your needs.

5. Factory Direct Supply

We provide direct factory pricing and fast delivery, with stable quality control.

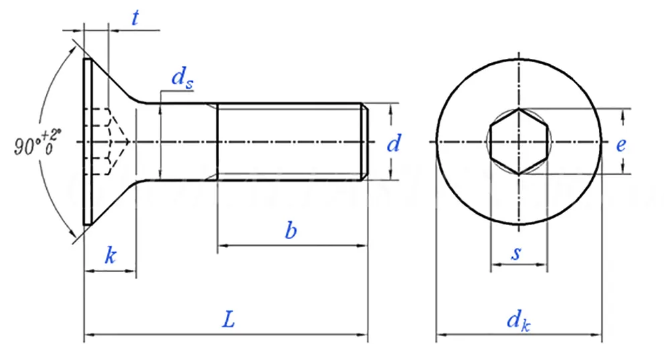

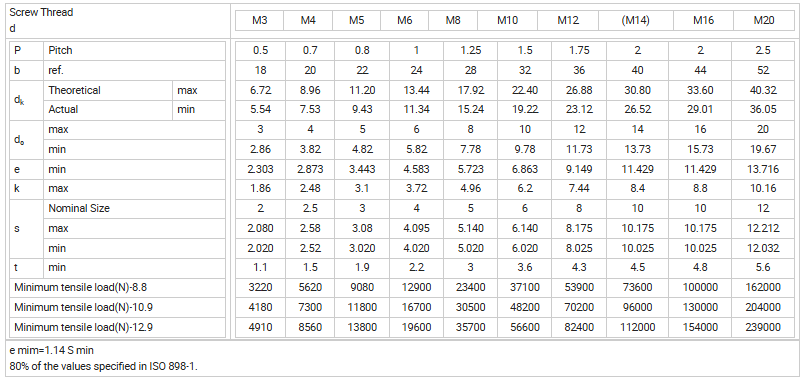

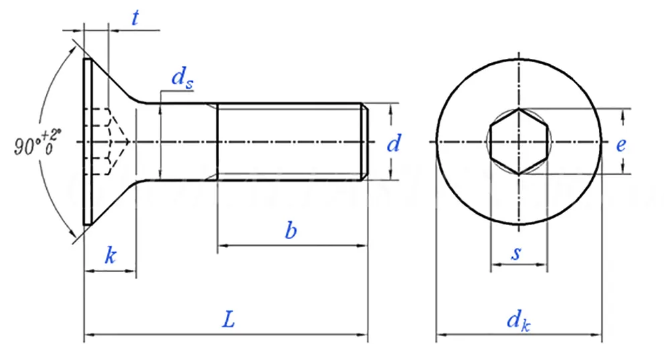

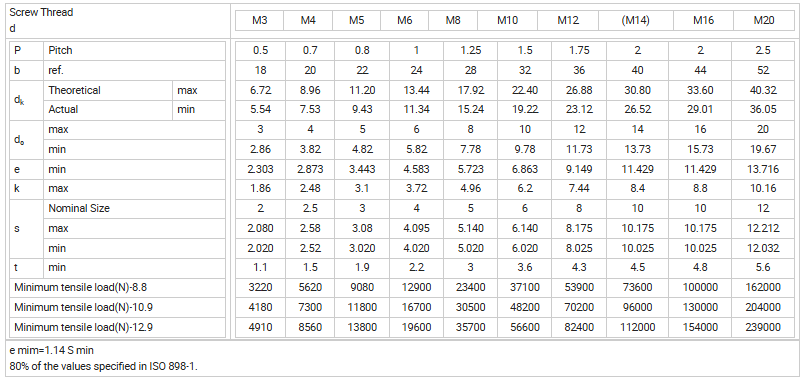

Technical Specifications of Titanium Countersunk Bolt

Product Name | Titanium Countersunk Bolt |

Material | Titanium Grade 2 / Grade 5 (Ti-6Al-4V) |

Standards | DIN 7991 / ISO 10642 / ASTM F136 / ASTM B348 |

size | M3–M20 |

Head Type | Counter Sunk Bolt |

Surface Finish | Polished / Pickled / Anodized |

Color Options | Natural titanium / Custom anodized colors |

MOQ | 100 pcs |

Packaging | Plastic Bag+ Carton+Wood Pallet |

Grade | 4.8/5.6/8.8/10.9 |

Specification | M4-M30/1/4"-8" |

Applications of Titanium Countersunk Bolt

Aerospace

aircraft structures, satellites, and spacecraft

Marine & Engineering

Ideal for ships, boats, and offshore installations

Automotive&Racing

engine assemblies, chassis, and custom builds

Bicycles & Sports Equipment

frames, saddles, and handlebars.

Medical Equipment

surgical instruments and implants (when using medical-grade titanium)

FAQ

Q1: What materials are used ?

Grade 2 or Grade 5 titanium

Q2: Can I order custom sizes and head styles?

Yes, we support full customization including size, thread, head shape, and surface finish.

Q3: What is the lead time?

lead time is typically 7 to 15 working days

Q4: What surface finishes are available?

Options include polished, pickled, and anodized finishes.

Q5: What is the minimum order quantity?

Our MOQ is 100 pieces.

Ordering Information

Standard items ship within 3-5 business days

Custom orders typically 2-4 week lead time

Competitive pricing for volume purchases

Worldwide shipping available