Key Properties

Exceptional Strength-to-Weight Ratio: GR5 Titanium Plate provides remarkable strength while maintaining a low density, making it up to 45% lighter than steel. This unique property allows for the creation of robust components that significantly reduce weight in critical applications, enhancing efficiency and performance.

Superior Corrosion Resistance: Exhibiting excellent resistance to a wide range of corrosive media, including seawater, acids, and alkaline solutions, GR5 titanium forms a passive oxide film on its surface, ensuring long - term protection and durability even in harsh environments.

High - Temperature Performance: Capable of maintaining its mechanical properties at elevated temperatures up to 400°C (752°F), GR5 titanium plates are suitable for applications that involve exposure to heat, such as aerospace engine components and industrial high - temperature equipment.

Good Fatigue Resistance: With enhanced resistance to cyclic loading, GR5 titanium is ideal for parts subjected to repeated stress, reducing the risk of fatigue failure and extending the service life of components.

Biocompatibility: GR5 titanium is biocompatible, making it a reliable choice for certain medical applications, especially those that require a combination of strength and compatibility with the human body, like complex orthopedic implants.

Chemical Composition

Element | Content (%) |

Titanium (Ti) | Balance |

Aluminum (Al) | 5.5 - 6.8 |

Vanadium (V) | 3.5 - 4.5 |

Iron (Fe) | ≤0.30 |

Oxygen (O) | ≤0.20 |

Nitrogen (N) | ≤0.05 |

Hydrogen (H) | ≤0.015 |

Other elements | Trace amounts |

Mechanical Properties

Dimensions and Tolerances

Thickness: Available from 0.5mm to 200mm, with strict thickness tolerances to ensure consistent quality across all products.

Width: Standard widths range from 600mm to 3000mm. Custom widths can be provided to meet specific project requirements.

Length: Custom - cut lengths are available, with standard lengths up to 6000mm, minimizing material waste and optimizing usage for various applications.

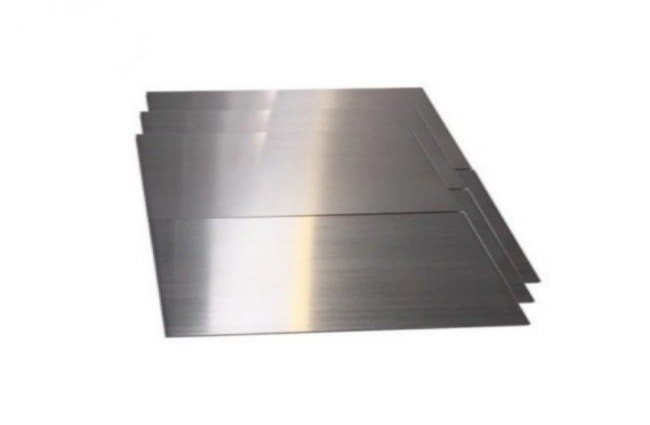

Surface Finish

Mill Finish: The standard finish obtained directly from the rolling process, providing a smooth, matte surface that is suitable for most general applications.

Polished Finish: A high - quality polished surface that not only enhances the aesthetic appeal but also improves corrosion resistance, making it ideal for applications where appearance and protection are important.

Pickled Finish: Removes the oxide layer formed during heat treatment, resulting in a clean, bright surface that is free from surface contaminants and ready for further processing or direct use.

Applications

Aerospace: Widely used in aircraft structures, such as fuselages, wings, and landing gear, as well as in engine components. Its high strength - to - weight ratio and excellent performance at high temperatures make it indispensable in the aerospace industry.

Medical: Employed in complex orthopedic implants, such as hip and knee replacements, due to its biocompatibility and high strength. It provides reliable support and durability within the human body.

Automotive: Used in high - performance automotive parts, including racing car frames, suspension components, and engine parts. The lightweight nature of GR5 titanium helps improve vehicle performance and fuel efficiency.

Marine: Ideal for marine applications, such as shipbuilding, offshore platforms, and underwater equipment. Its corrosion resistance ensures long - term reliability in seawater environments.

Industrial: Applied in industrial equipment, such as chemical reactors, heat exchangers, and pumps, where resistance to harsh chemicals and high - temperature conditions is required.

Quality Assurance

At BYC Ti, quality is our top priority. Each GR5 Titanium Plate undergoes a comprehensive quality control process:

Raw Material Inspection: Rigorous testing of incoming raw materials to ensure compliance with chemical and mechanical specifications.

In - Process Monitoring: Continuous monitoring during the manufacturing process, including rolling, heat treatment, and cutting, to ensure dimensional accuracy and property consistency.

Final Testing: Every plate is subjected to non - destructive testing (such as ultrasonic and radiographic testing), mechanical property testing, and chemical analysis. Only products that meet or exceed international standards, including ASTM B265, ASME SB - 265, and ISO 5832 - 3, are approved for shipment.

Customization Options

We understand that each project has unique requirements. Therefore, we offer a wide range of customization services:

Size and Shape Customization: Tailor - made plates in specific thicknesses, widths, and lengths to fit your exact project needs.

Surface Treatment Customization: Customized surface finishes, including special coatings or textures, to enhance functionality or appearance.

Mechanical Property Customization: Through heat treatment and other processes, we can adjust the mechanical properties of the plates to meet specific application requirements.

Ordering and Delivery

Ordering our GR5 Titanium Plates is straightforward. Contact our sales team with your detailed specifications, and we will provide you with a competitive quote promptly. We offer flexible delivery options, ensuring that your order is shipped securely and arrives on time, whether you require small - batch orders or large - scale deliveries.