Why Choose Titanium Hex Nuts?

Lightweight & Strong – 40% lighter than steel with comparable strength.

Corrosion-Resistant – Immune to saltwater, acids, and industrial chemicals.

High-Temperature Stability – Maintains integrity up to 600°F (315°C).

Non-Magnetic – Safe for MRI and sensitive electronics.

Biocompatible (Grade 23) – Ideal for medical implants and surgical tools.

Technical Specifications

Parameter | Specification |

Thread Standards | UNC, UNF, Metric |

Sizes | M3 to M36 (metric), #4-40 to 1½" (imperial) |

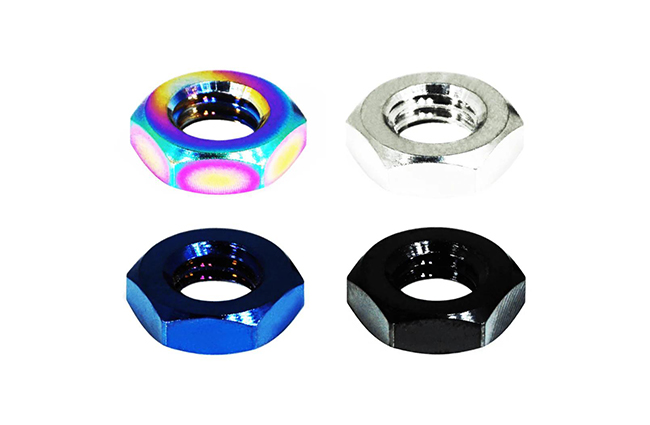

Surface Finishes | Plain, polished, anodized, DLC-coated |

Tensile Strength | 240–1000 MPa (varies by grade) |

Torque Values | 10–150 Nm (grade-dependent) |

Applications by Industry

Aerospace – Aircraft structural fasteners, engine mounts

Marine – Boat hardware, offshore platforms

Medical – Surgical instruments, prosthetics

Automotive – High-performance engines, racing components

Manufacturing & Quality Assurance

1. Precision CNC Machining – Ensures tight tolerances (±0.01mm).

2. Thread Rolling – Enhances fatigue resistance.

3. Heat Treatment – Optimizes mechanical properties.

4. 100% Inspection – Dimensional checks.

Why Partner With Us?

Full Material Traceability – Mill test certificates provided.

Custom Options – Special sizes, coatings, and threading.

Fast Shipping – Standard sizes ship in 3–5 business days.

Material Options & Properties

Grade | Key Features | Best For |

Grade 1 (CP Titanium) | Excellent corrosion resistance | Marine, chemical processing |

Grade 2 (CP Titanium) | Balanced strength & corrosion resistance | General industrial use |

Grade 5 (Ti-6Al-4V) | High strength-to-weight ratio | Aerospace, racing |

Grade 7 (Ti-0.15Pd) | Superior acid resistance | Chemical plants |

Grade 23 (Ti-6Al-4V ELI) | Medical-grade, extra-low interstitials | Surgical implants |

Request a Quote Today! – Bulk pricing available for manufacturers and wholesalers.

Frequently Asked Questions

Q: Which grade is best for saltwater exposure?

A: Grade 7 (Ti-0.15Pd) offers the highest corrosion resistance in marine environments.

Q: Can I reuse titanium hex nuts?

A: Yes, if properly torqued and undamaged.

Q: Do you offer nylon-insert lock nuts?

A: Yes, in Grades 2, 5, and 23.

Q: Are these compliant with aerospace standards?

A: Yes, we meet ASTM requirements.