Why Titanium Brake Caliper Bolts?

Corrosion Resistance – Immune to rust, brake fluid, and road salts (ideal for coastal and winter riding).

Lightweight Strength – Grade 5 (Ti-6Al-4V) offers 1,000 MPa tensile strength at half the weight of steel.

Heat Resistance – Stable up to 500°F (260°C), perfect for high-performance braking systems.

Non-Galling – DLC-coated options reduce friction during installation.

Biocompatible (Grade 23) – Safe for medical and sensitive applications.

Technical Specifications

Parameter | Specification |

Diameter | M8, M10 (custom sizes available) |

Length | 50–70mm (varies by bike model) |

Thread Pitch | 1.25mm (standard), fine threads optional |

Head Type | Hex socket (DIN 912) |

Torque Rating | 40–60 Nm (grade-dependent) |

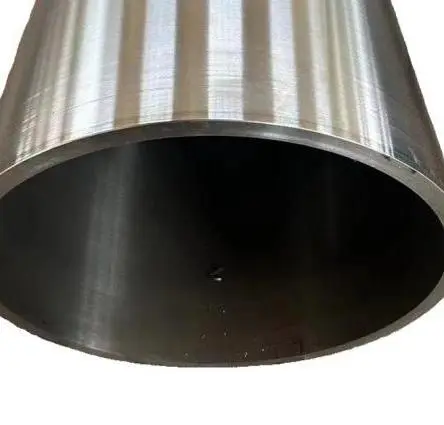

Surface Finishes | Polished, anodized, DLC-coated |

Manufacturing & Quality Assurance

Precision Forging.

Thread Rolling – Cold-formed for 30% higher fatigue resistance.

Heat Treatment – Optimized for each titanium grade.

Material Options & Applications

Grade | Key Features | Best For |

Grade 2 | Cost-effective, excellent corrosion resistance | Street bikes, general use |

Grade 5 (Ti-6Al-4V) | High strength-to-weight ratio | Racing, track bikes |

Grade 7 (Ti-0.15Pd) | Superior acid resistance | Chemical exposure, coastal areas |

Grade 23 (Ti-6Al-4V ELI) | Enhanced fracture toughness | Medical/ aerospace applications |

Why Choose Us?

Full Material Traceability – Mill test certificates included.

Custom Options – Special lengths, coatings, and threading.

Fast Shipping – Standard sizes ship in 3–5 business days.

Request a Quote Today! – Bulk pricing available for manufacturers and wholesalers.

Frequently Asked Questions

Q: How much weight do I save vs. steel?

A: ~40% reduction (e.g., 113g titanium vs. 190g steel for 4 bolts).

Q: Can I reuse these bolts?

A: Yes, if undamaged and torqued correctly.

Q: Are these track-legal?

A: Yes.

Ordering Information

Custom orders: 2–4 week lead time.

Global shipping: DHL/FedEx options.

Contact our titanium experts for fitment guidance and volume discounts!