Key Features

Superior Corrosion Resistance – Ideal for saltwater, chemical, and high-moisture environments.

High Strength-to-Weight Ratio – Stronger than steel yet significantly lighter for weight-sensitive applications.

Integrated Flange Design – Provides a wider bearing surface to distribute load, reducing the risk of loosening under vibration.

Temperature Resistant – Maintains structural integrity in extreme temperatures.

Smooth, Precision Threads – Ensures a secure and reliable fit with compatible titanium or other alloy bolts.

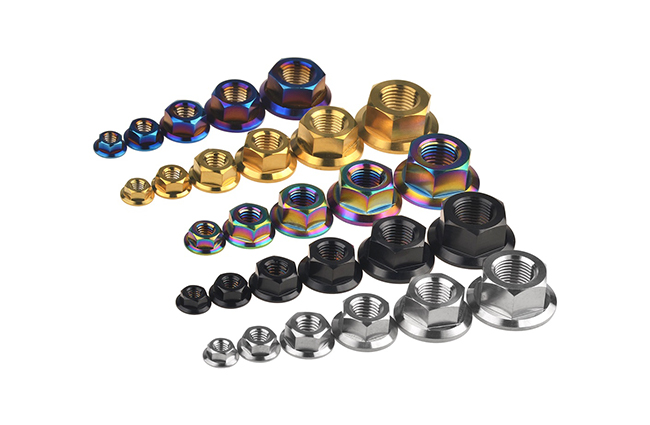

Available in Multiple Finishes – Natural titanium, anodized, or custom coatings upon request.

Applications of Titanium Flange Nuts

Titanium flange nuts are indispensable in industries where high strength, lightweight properties, and corrosion resistance are critical. Below are key sectors and specific use cases:

1. Aerospace & Aviation

Airframe Assemblies – Used in structural joints to reduce weight while maintaining tensile strength comparable to steel.

Jet Engines – Withstand extreme temperatures (up to 500°C) and resist oxidation in high-pressure environments.

Satellite & Spacecraft – Preferred for their radiation resistance and ability to endure thermal cycling.

2. Automotive & Motorsports

High-Performance Engines – Serrated flange nuts prevent loosening under vibration in racing engines.

Lightweight Chassis – Reduce unsprung weight in motorcycles and cars, improving acceleration and fuel efficiency.

Suspension Systems – M6–M10 flange nuts secure top mounts and control arms in corrosive environments (e.g., off-road vehicles).

3. Marine & Offshore

Boat Fittings – Resist saltwater corrosion in hull fastenings, rigging, and underwater equipment.

Oil & Gas Pipelines – Paired with titanium flanges for subsea connections, offering longevity in saline and acidic conditions.

4. Medical & Chemical

Surgical Instruments – Biocompatible (Grade 2/5) and sterilizable for implants and MRI machine components.

Chemical Processing – Ideal for reactors and pumps handling corrosive fluids (e.g., chlorine, sulfuric acid).

5. Industrial & Renewable Energy

Wind Turbines – Hex flange nuts secure turbine blades and nacelles, enduring weather extremes without galvanic corrosion.

Nuclear Power Plants – Grade 5 titanium’s radiation resistance makes it suitable for reactor fittings.

6. Consumer & Custom Applications

Bicycles & Motorcycles – Upgrade kits for axles.

Custom Machinery – Swivel flange nuts adapt to non-perpendicular surfaces in robotics and automation.

Specifications (Standard)

Material: Titanium (Grade 2, Grade 5, or custom alloys)

Standards: DIN, ANSI, ISO, or customer-specified.

Thread Sizes: M3 to M30 (or imperial sizes upon request).

Finish: Natural, anodized, or specialty coatings.

Why Choose Our Titanium Flange Nuts?

Our nuts are precision-machined to meet strict tolerances, ensuring a perfect fit every time. Whether you need standard sizes or custom-engineered solutions, we provide fasteners that outperform steel and aluminum alternatives in extreme conditions.

Request a Quote Today! – Contact us for bulk orders, custom dimensions, or material certifications.